Oil pump facts:

oil supply is only 50% filtered

http://www.mye28.com/viewtopic.php?p=954115

http://www.mye28.com/viewtopic.php?p=954115

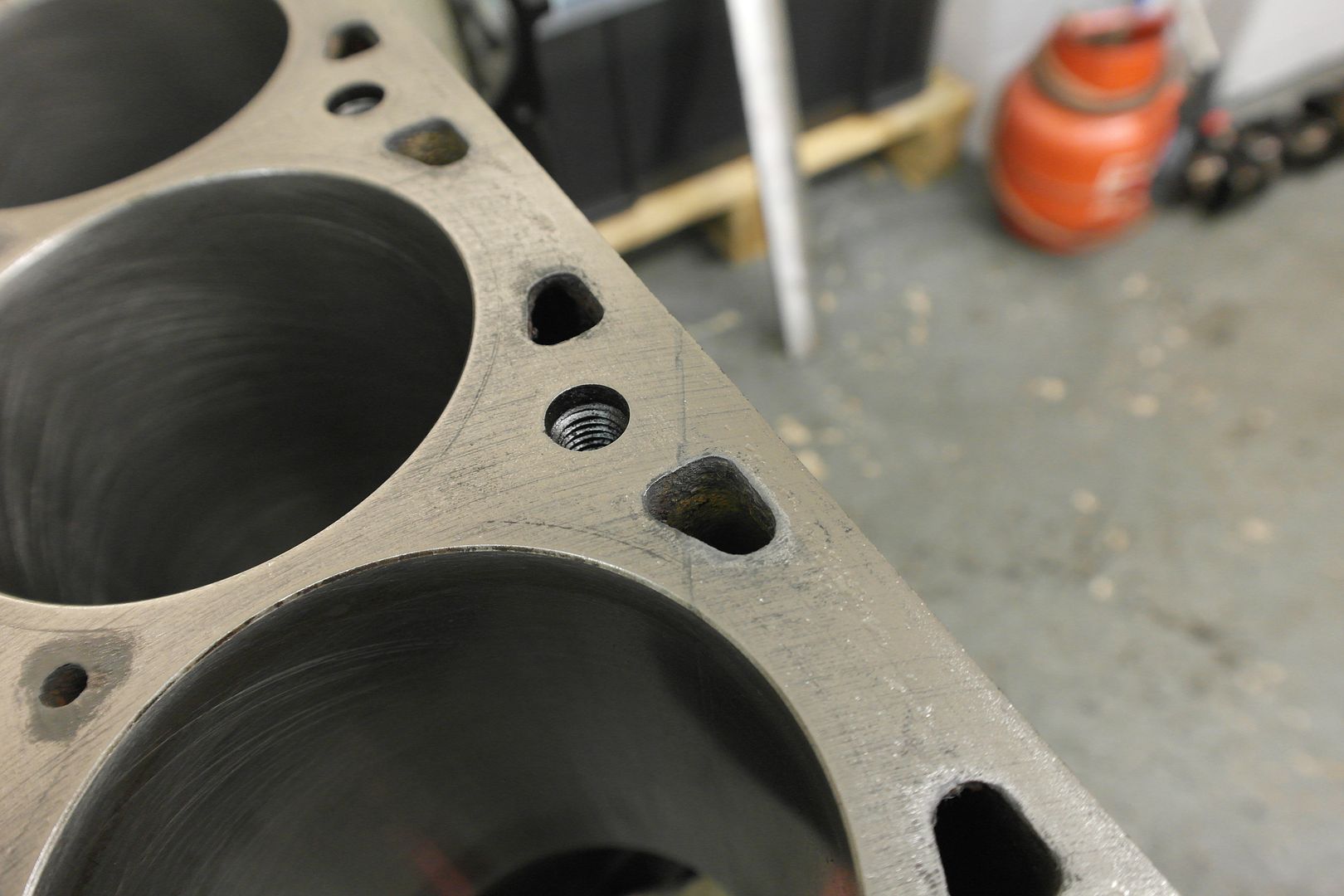

see above regarding oil deck restrictors.

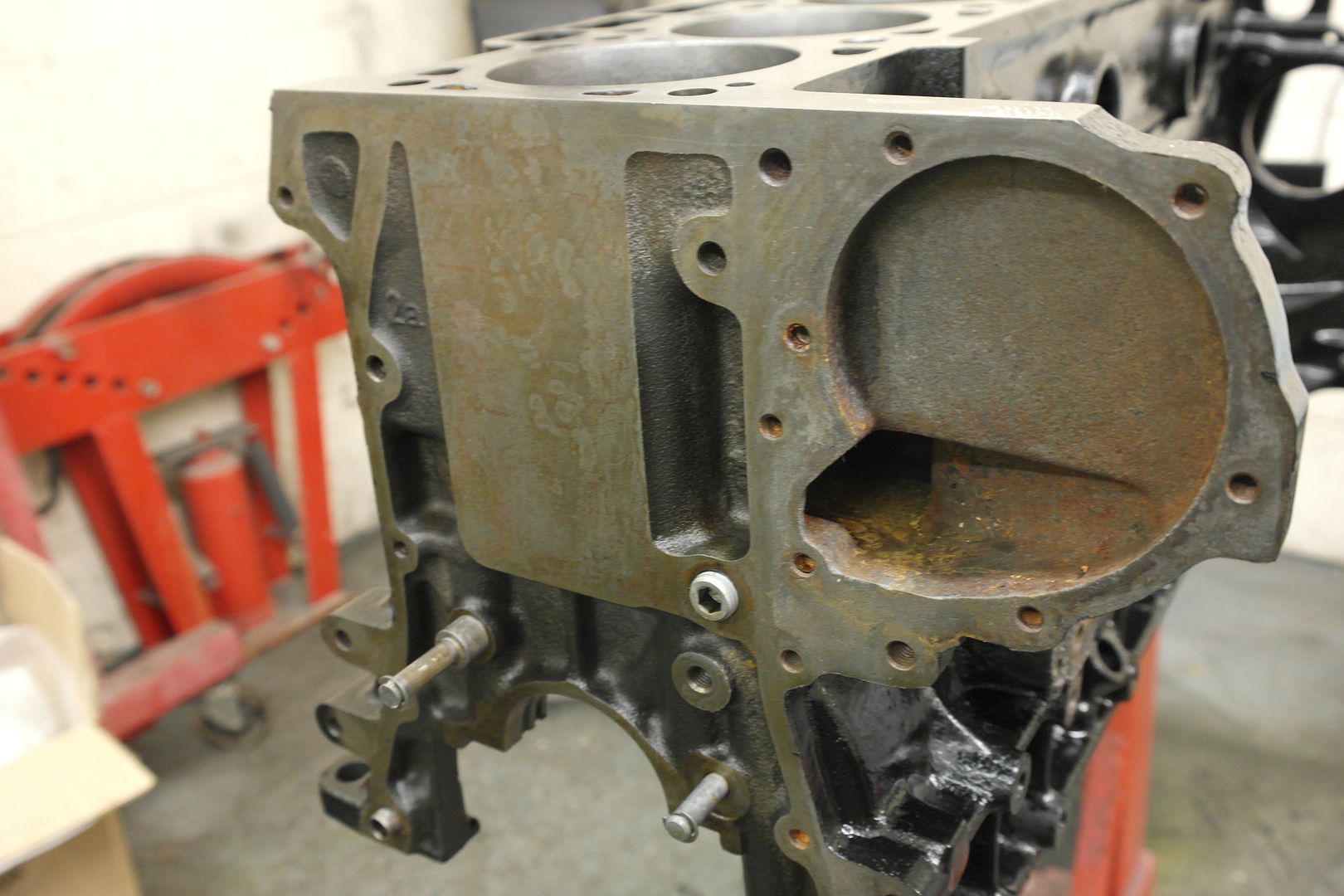

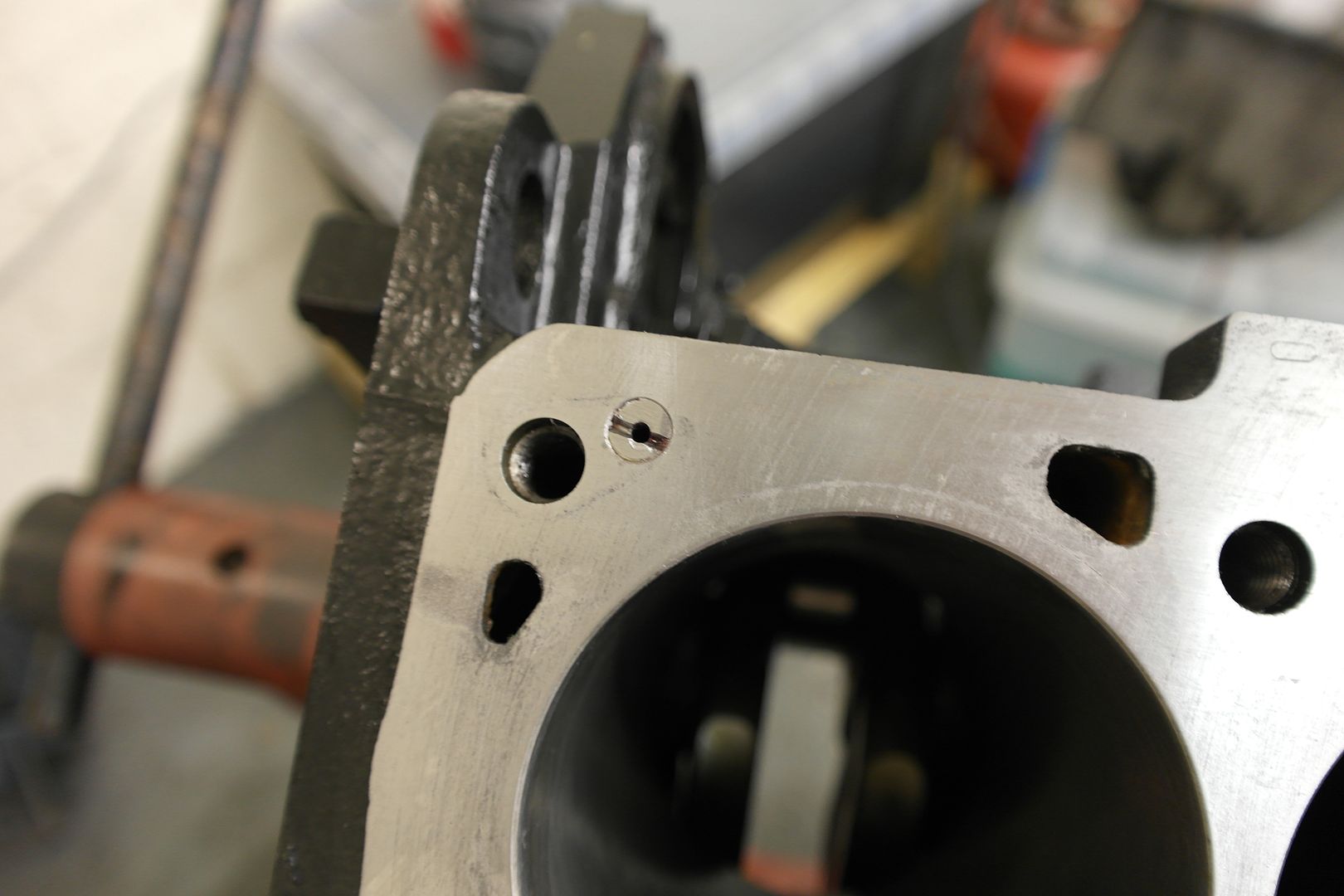

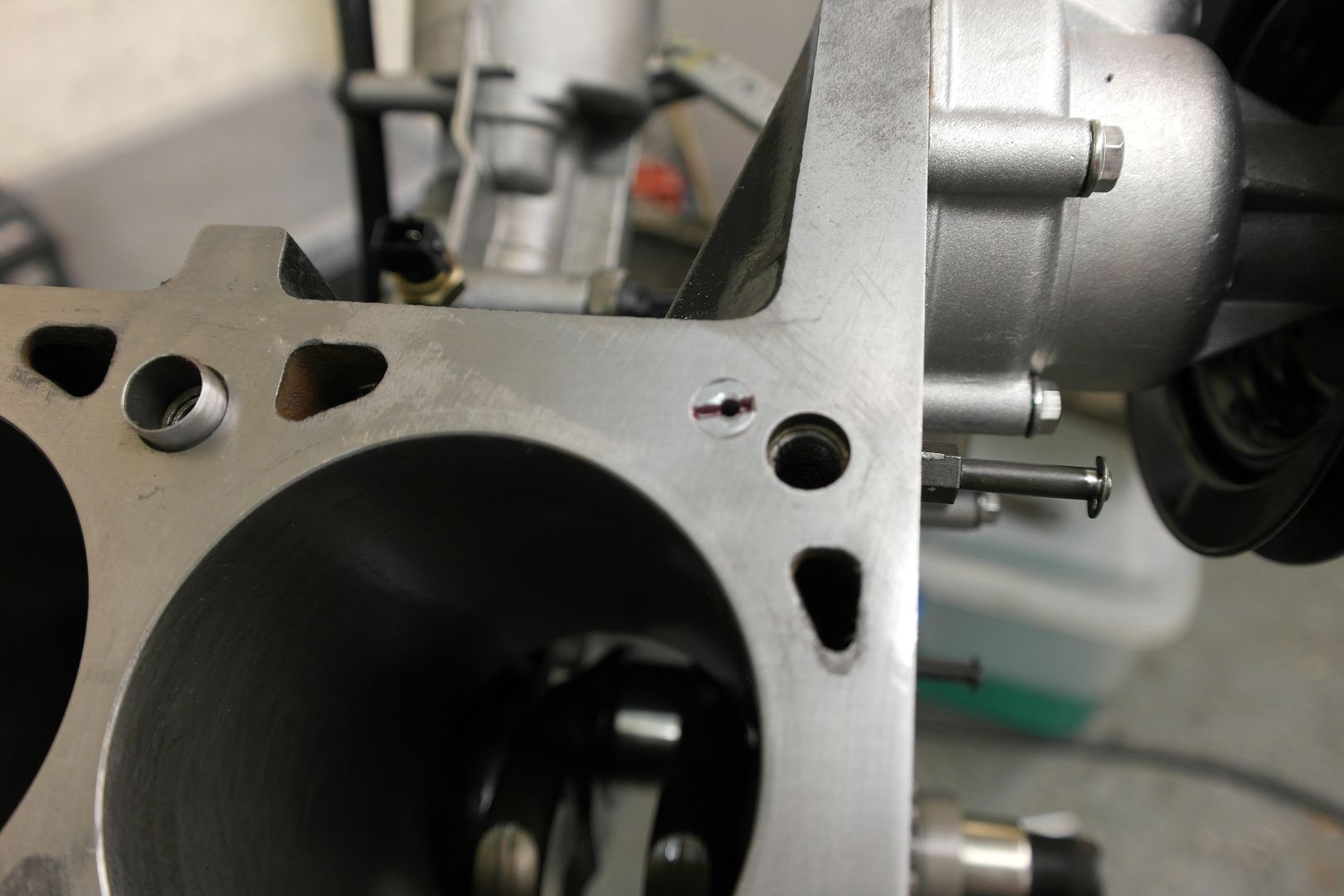

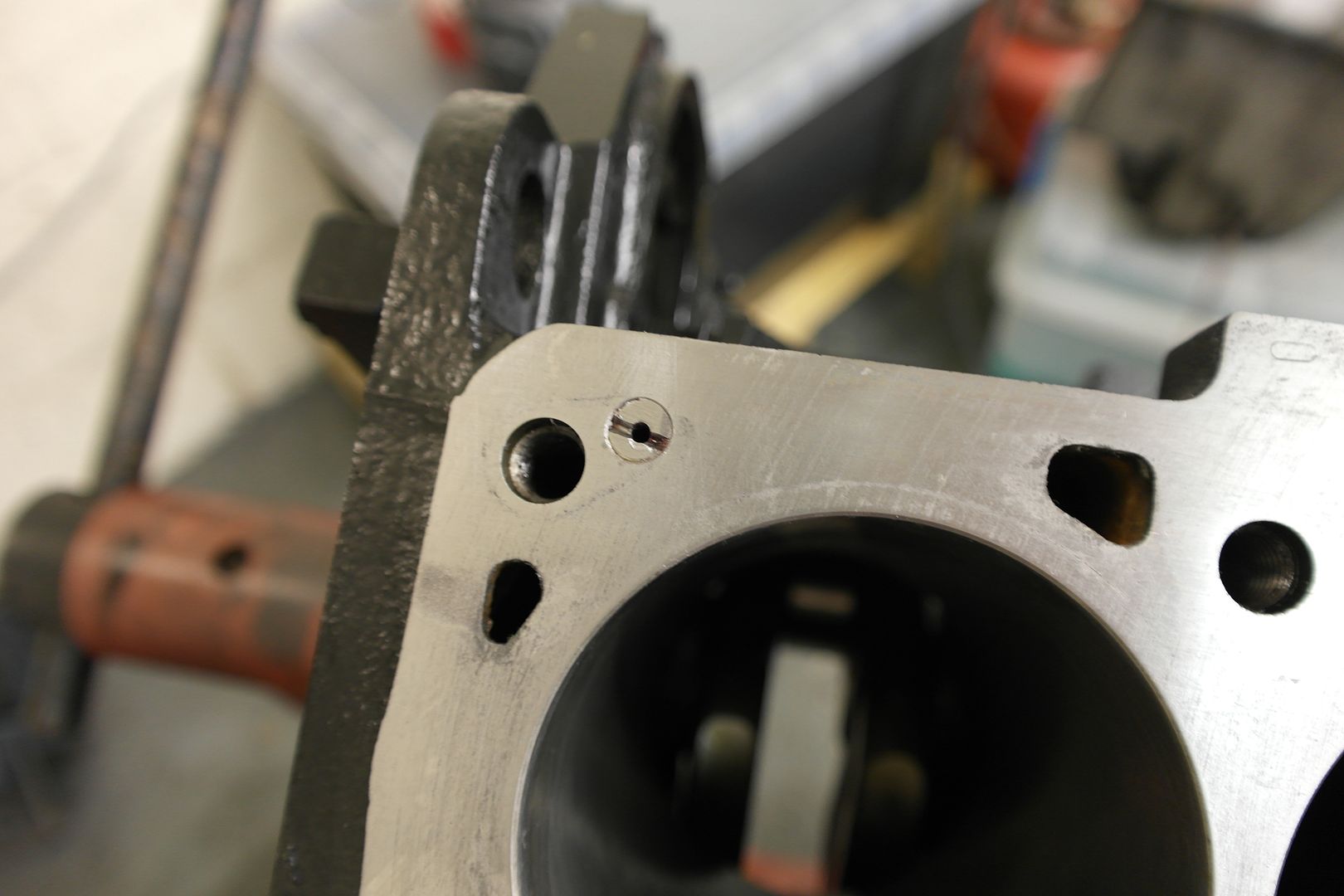

Fwd supply hole supplies direct to engine, aft supply hole is straight to the filter housing via the check valve in the canister.

Put the air line on it to check.

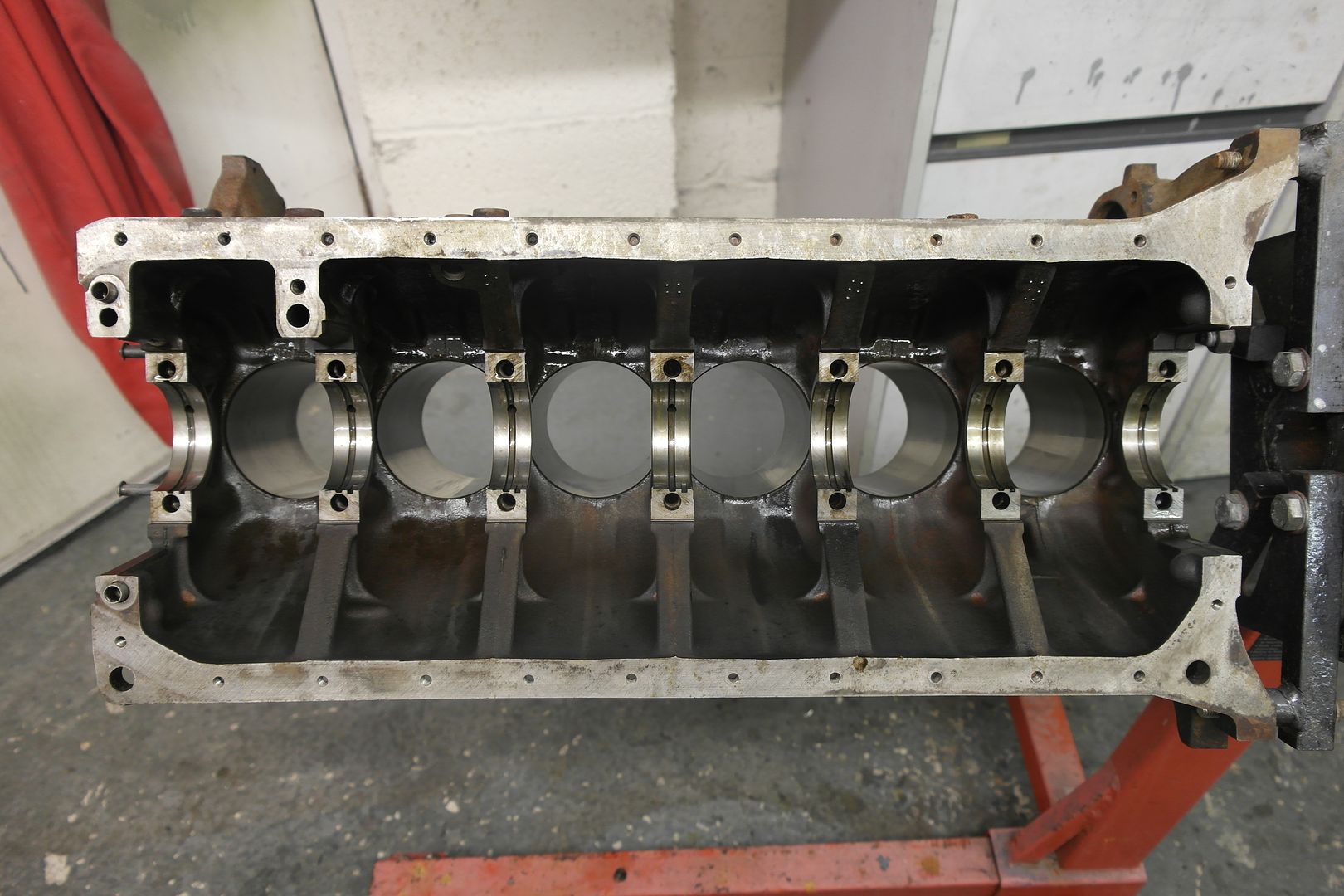

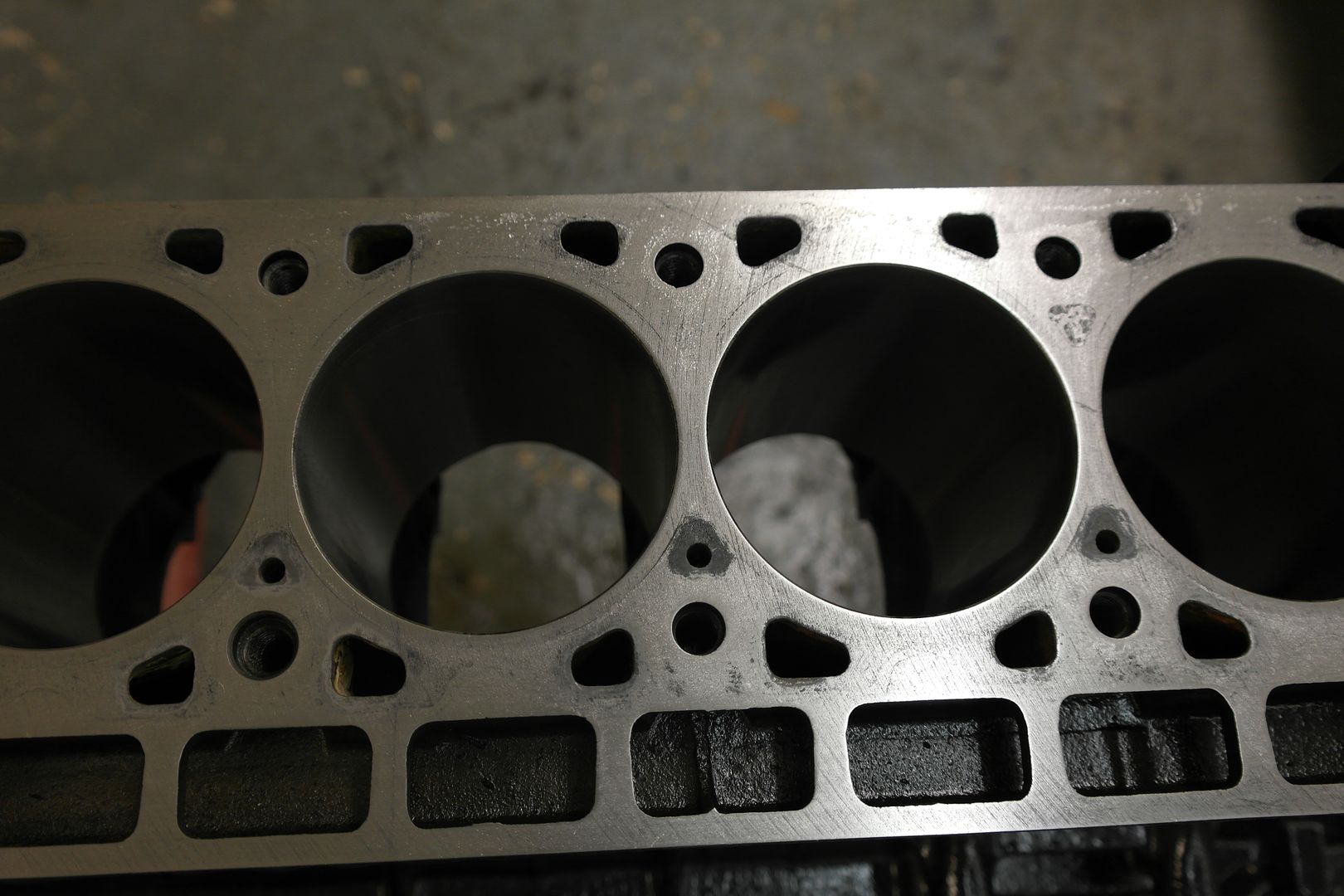

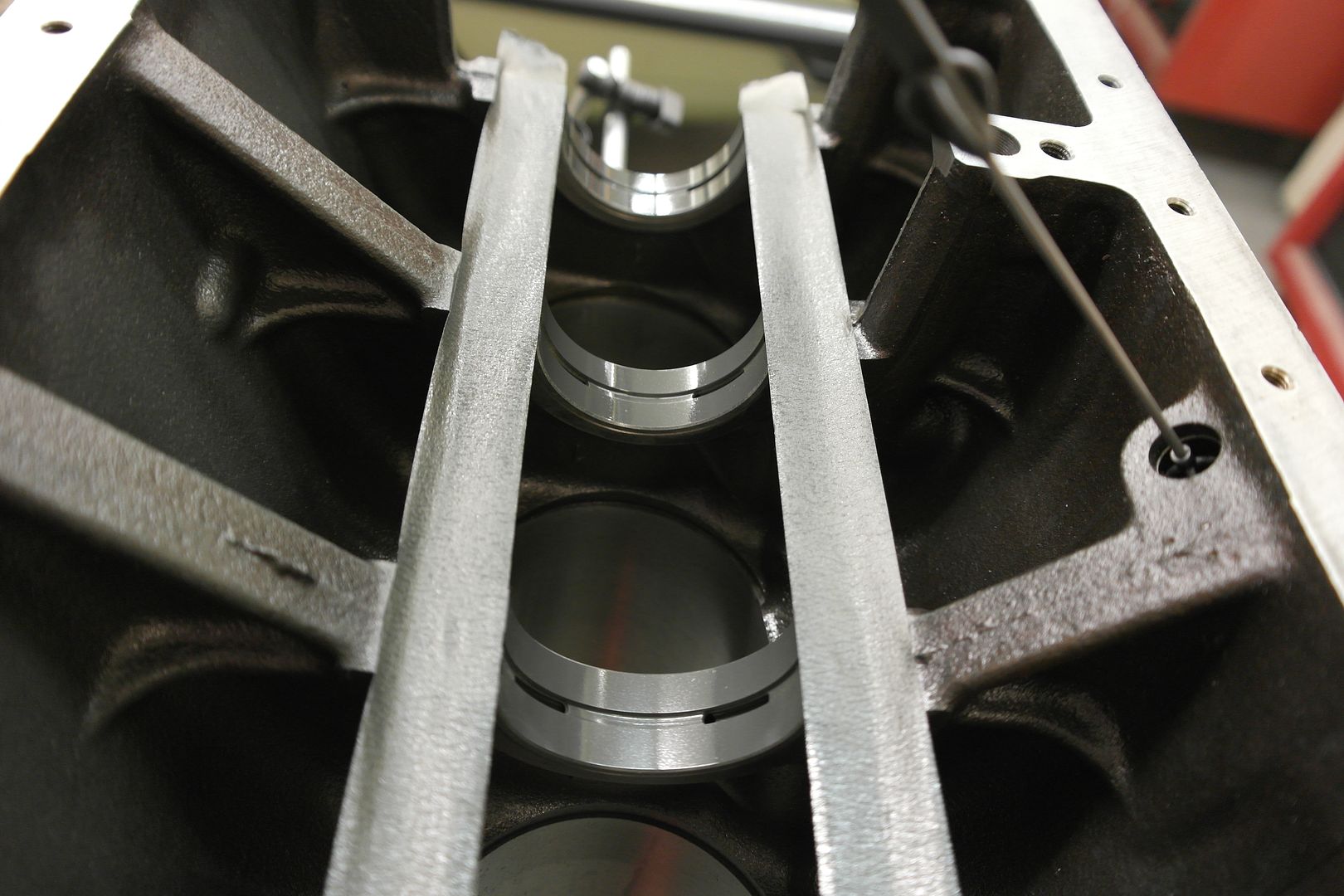

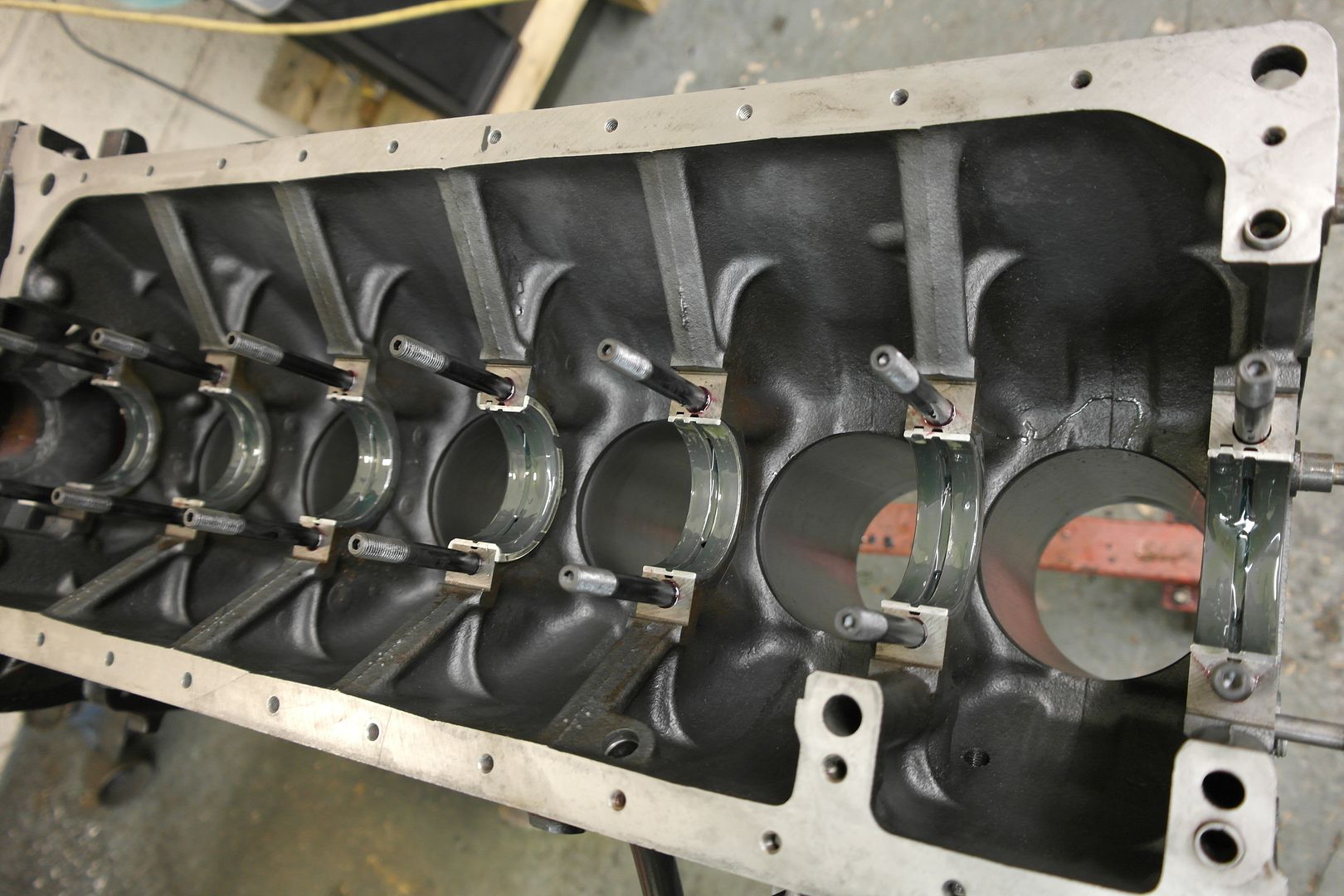

Both head supplies where filled with heavy grease, drilled to 8.5mm and tapped m10x1.5

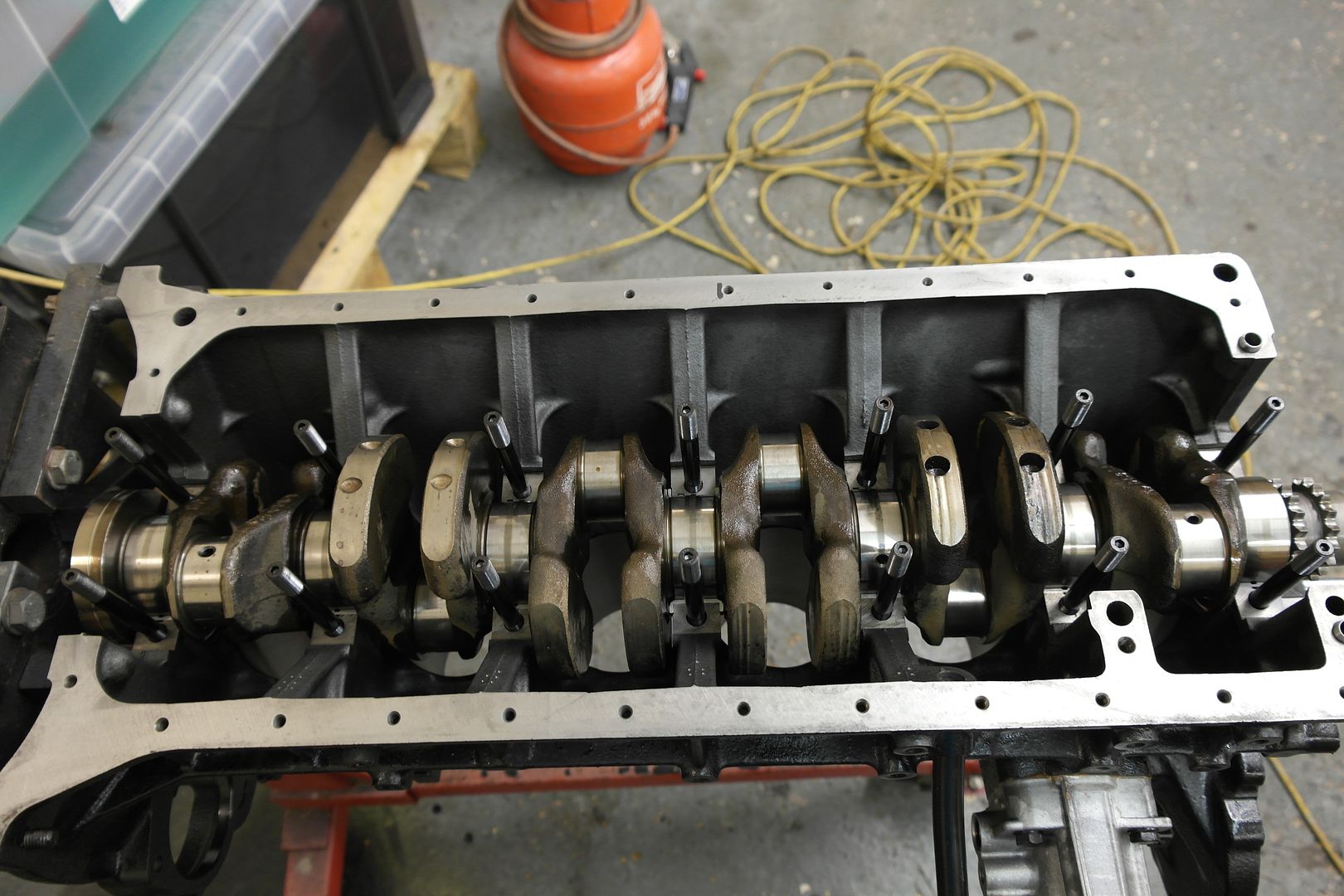

rotate block, fill supply line with ATF and blown through to clear any debris.

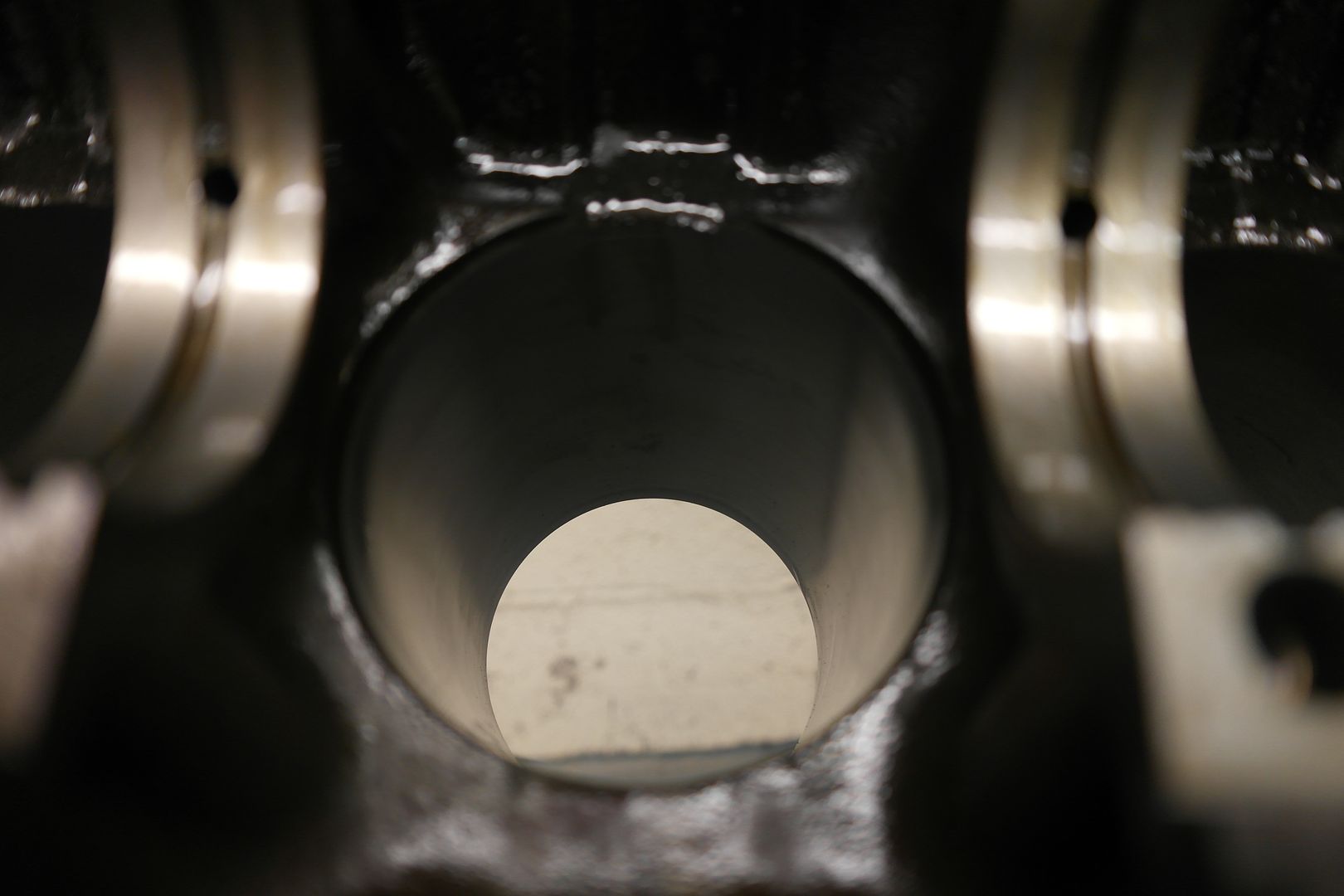

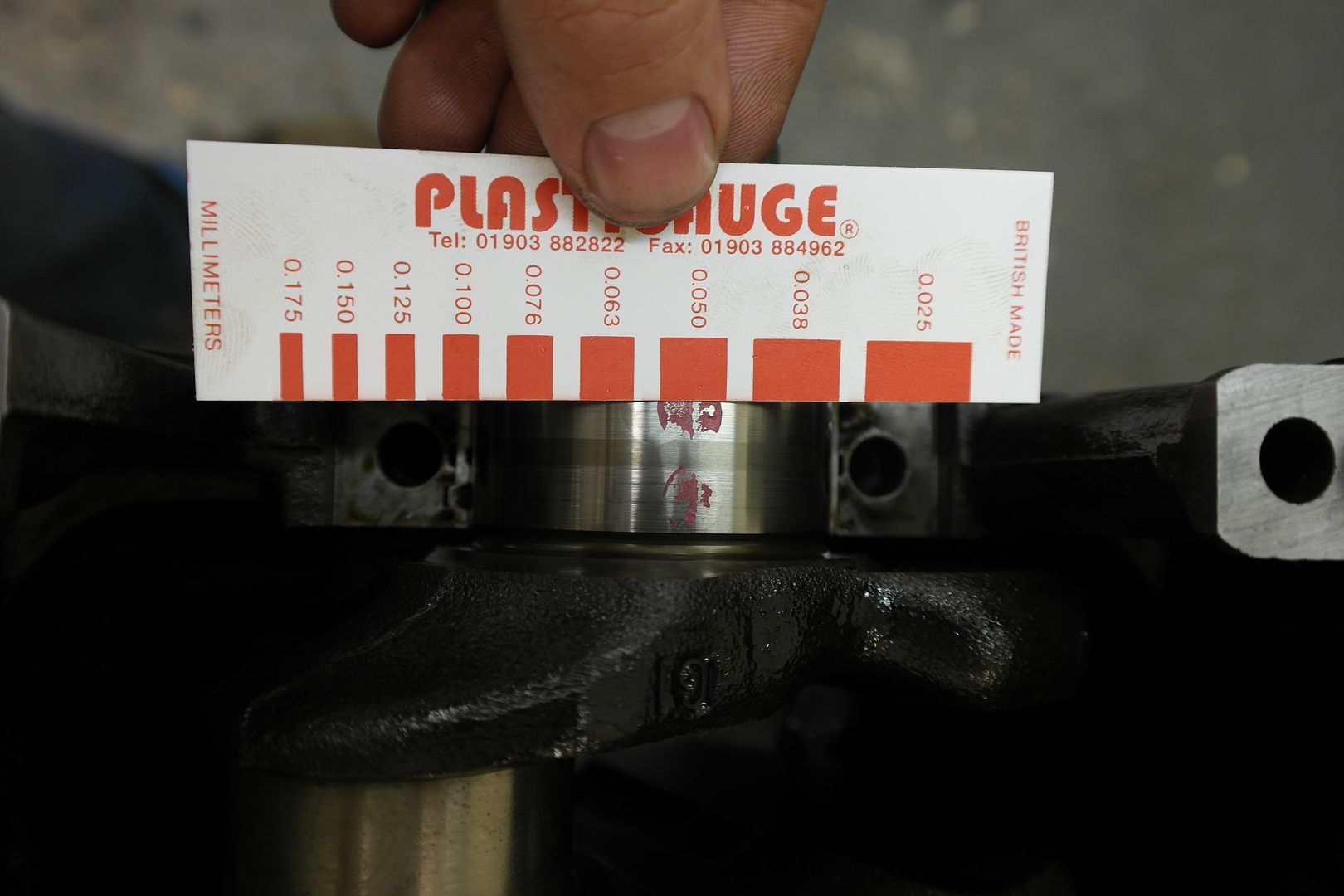

Yes I didn't know about this before I installed the crank hence the heavy grease.

drill 3mm hole and slot for install

I can see the merits of this mod, and i do like to drive engine hard, now and then.

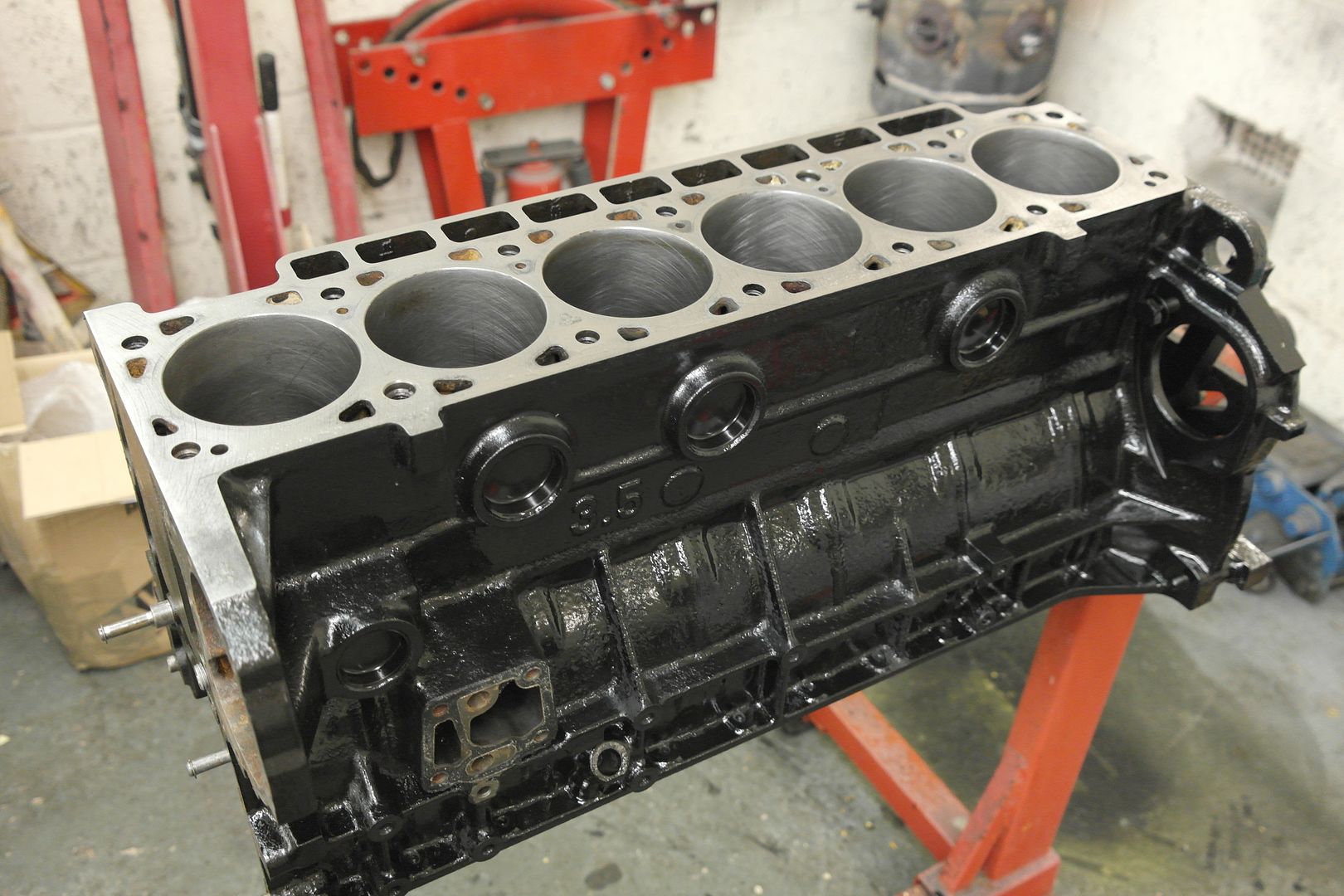

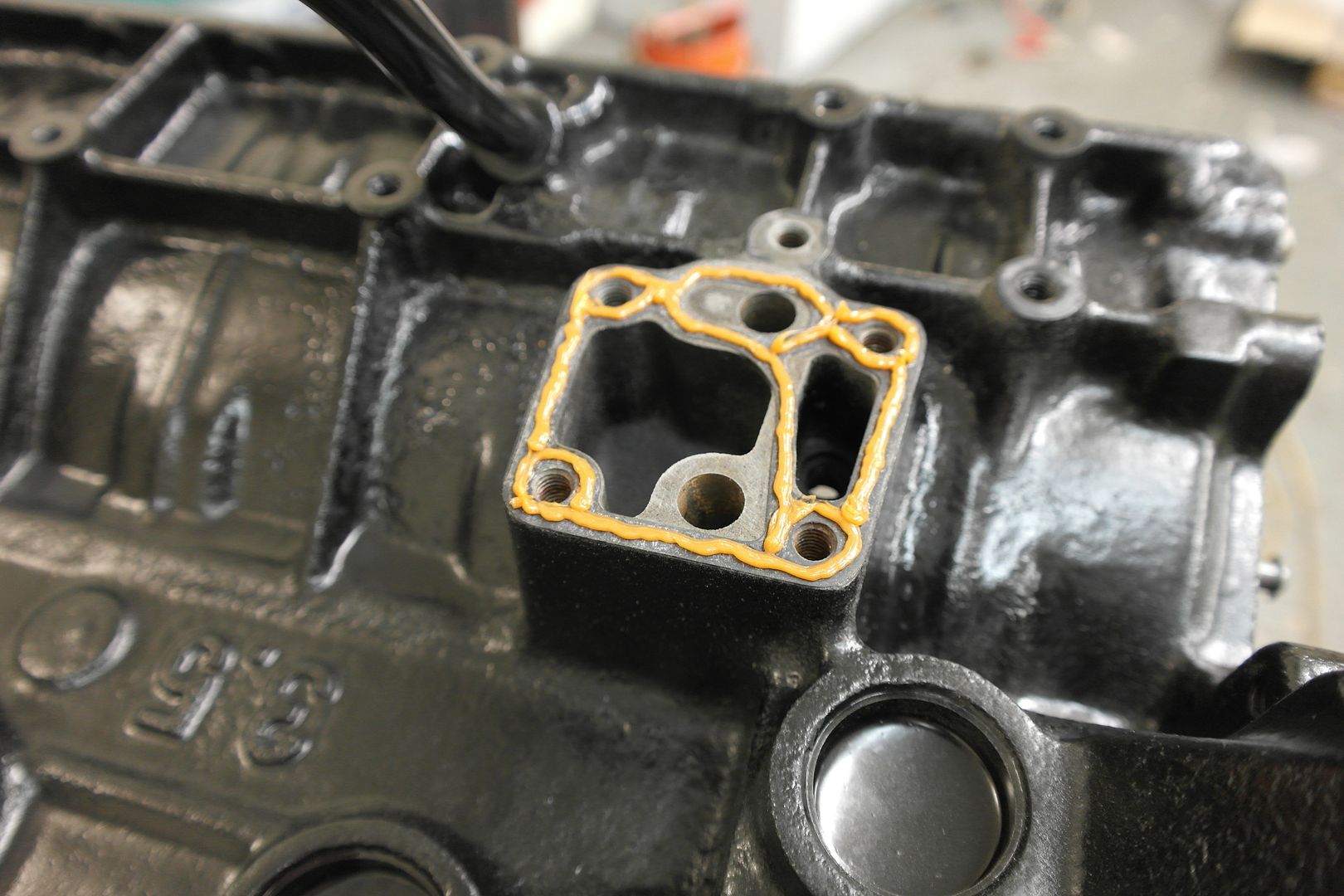

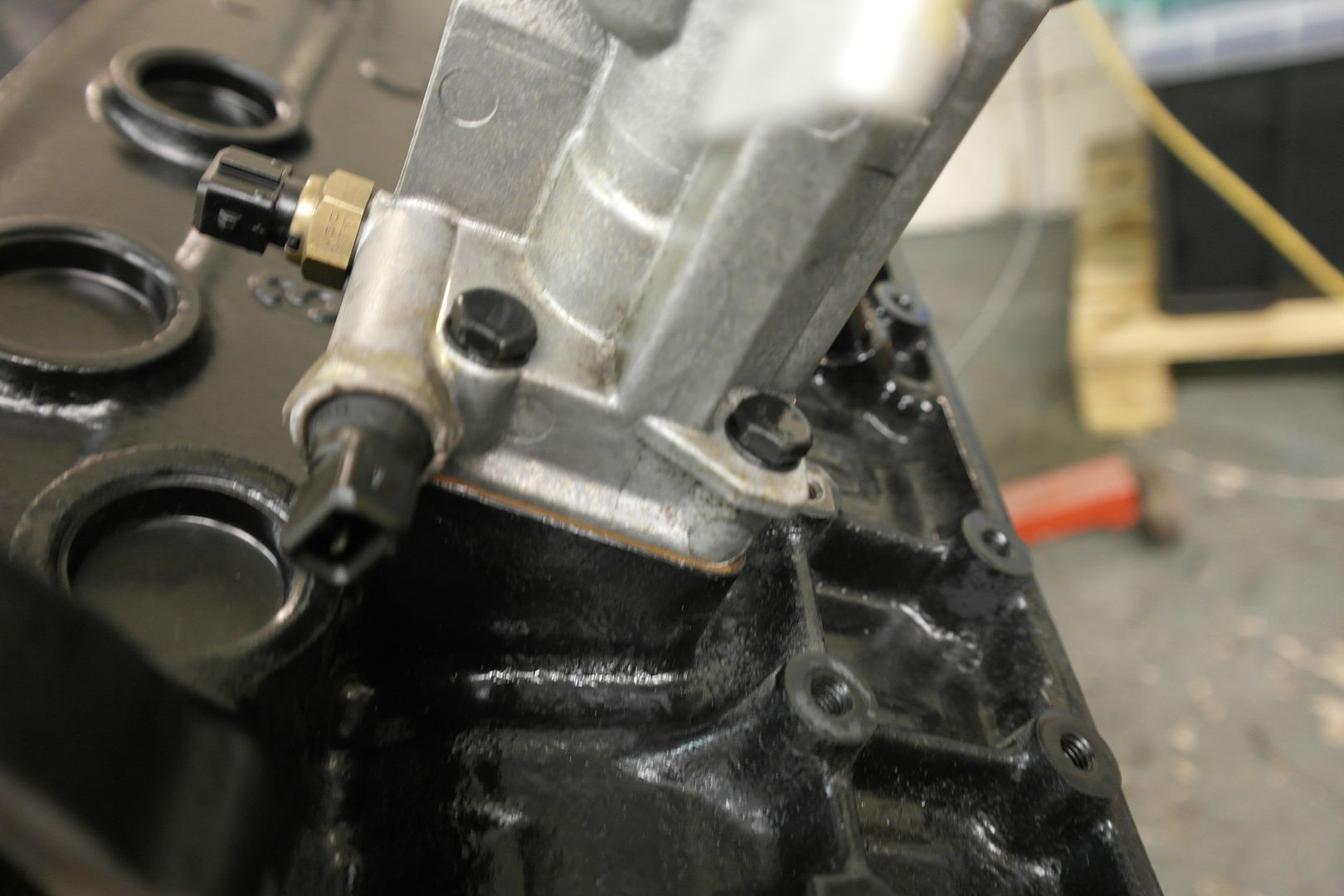

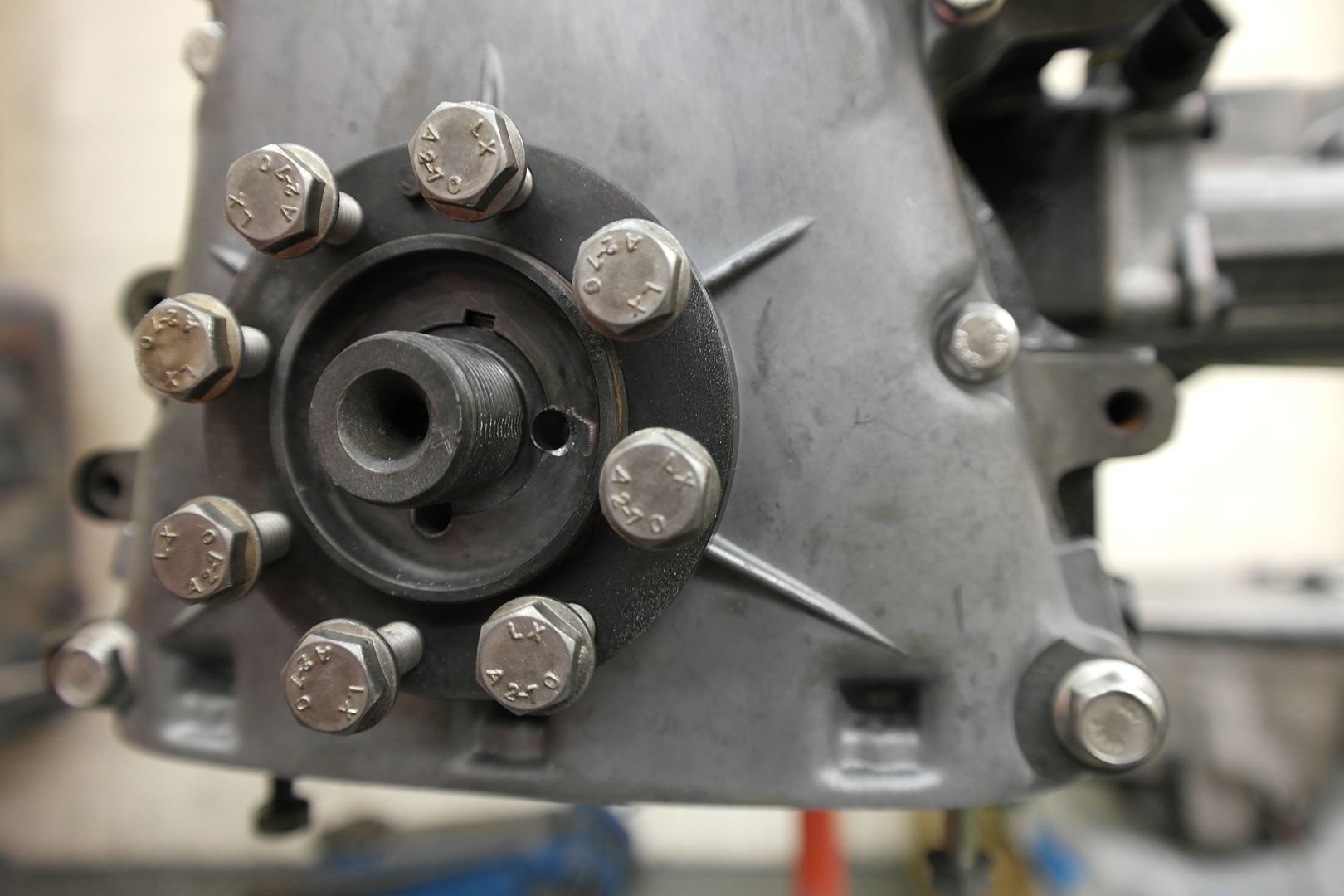

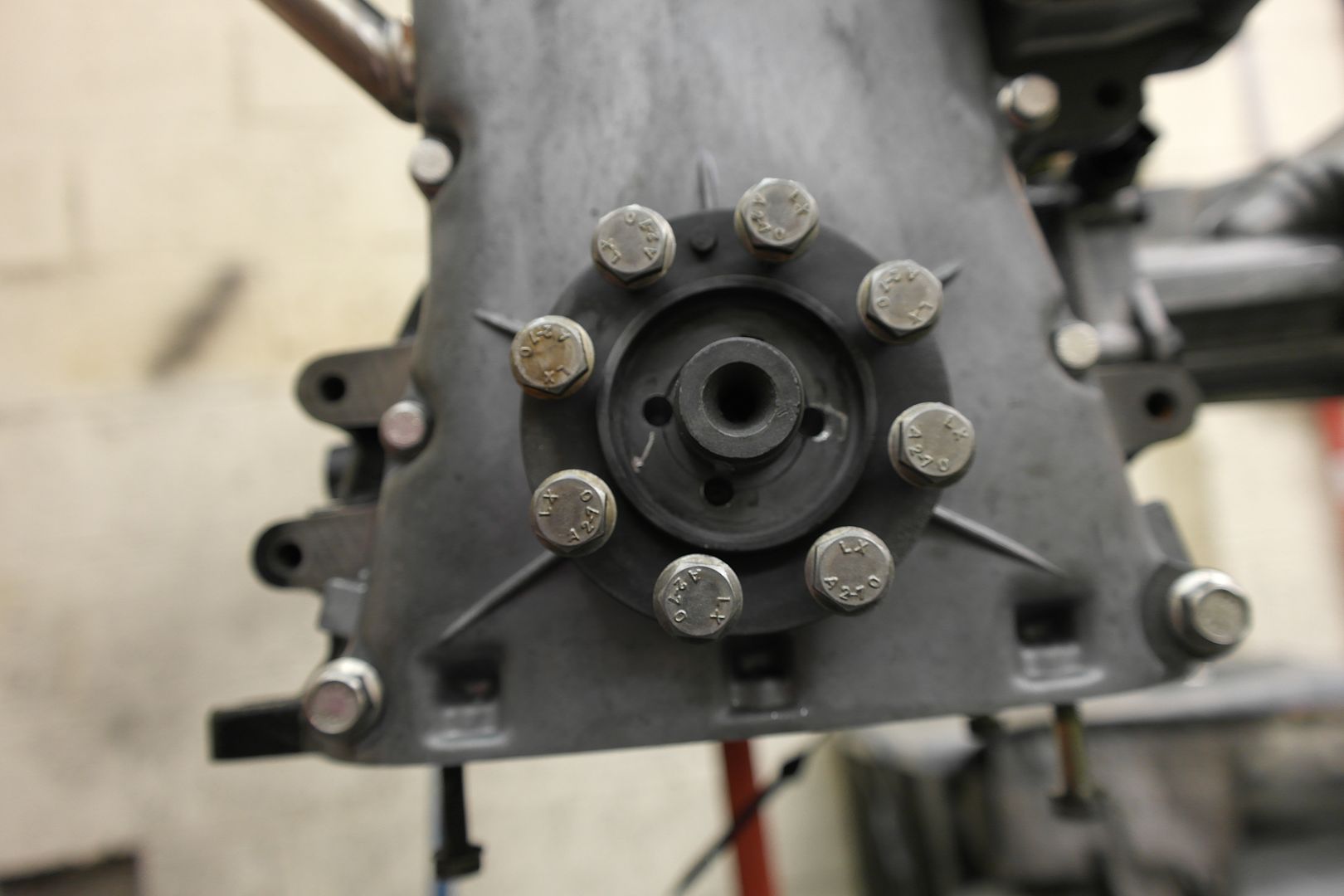

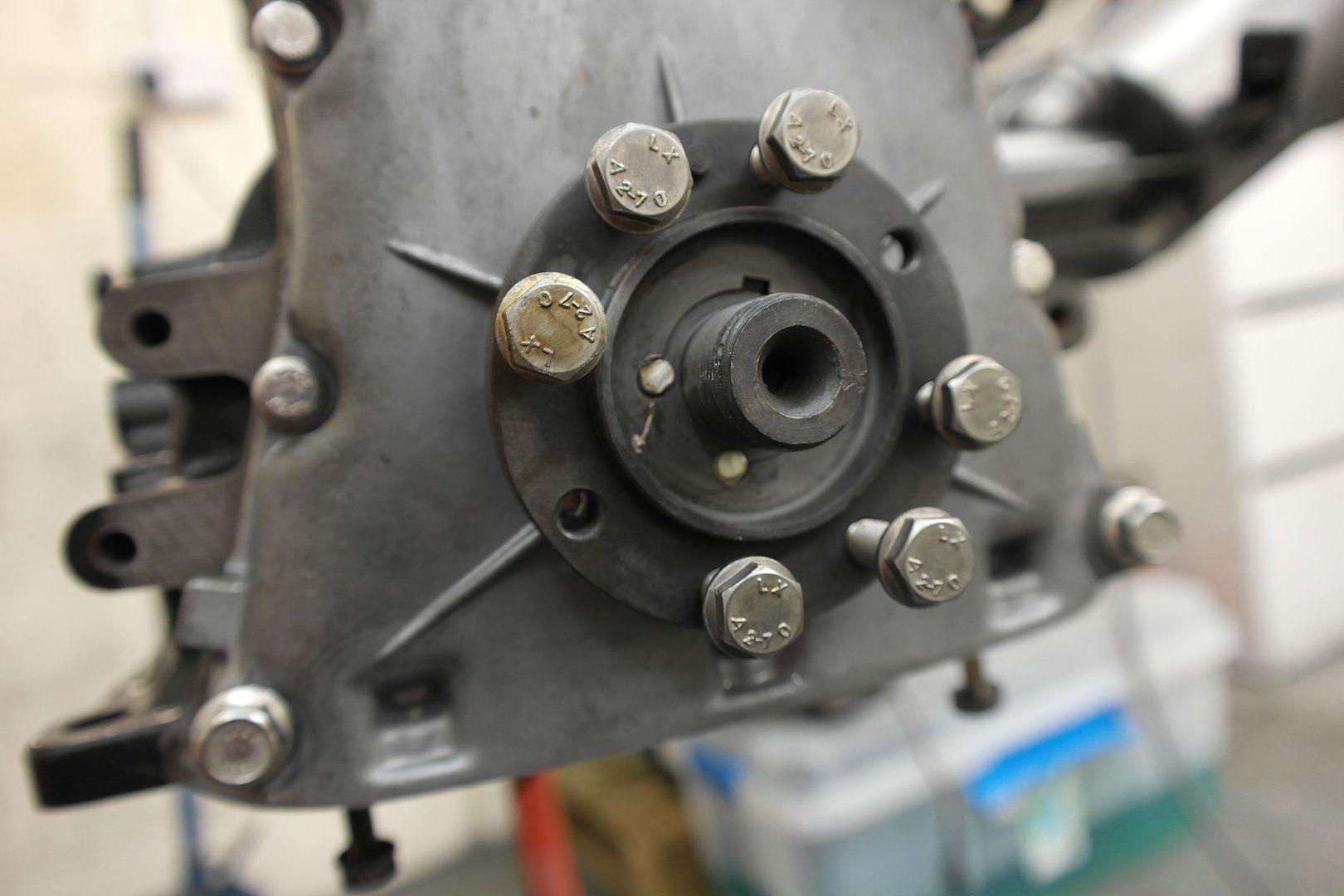

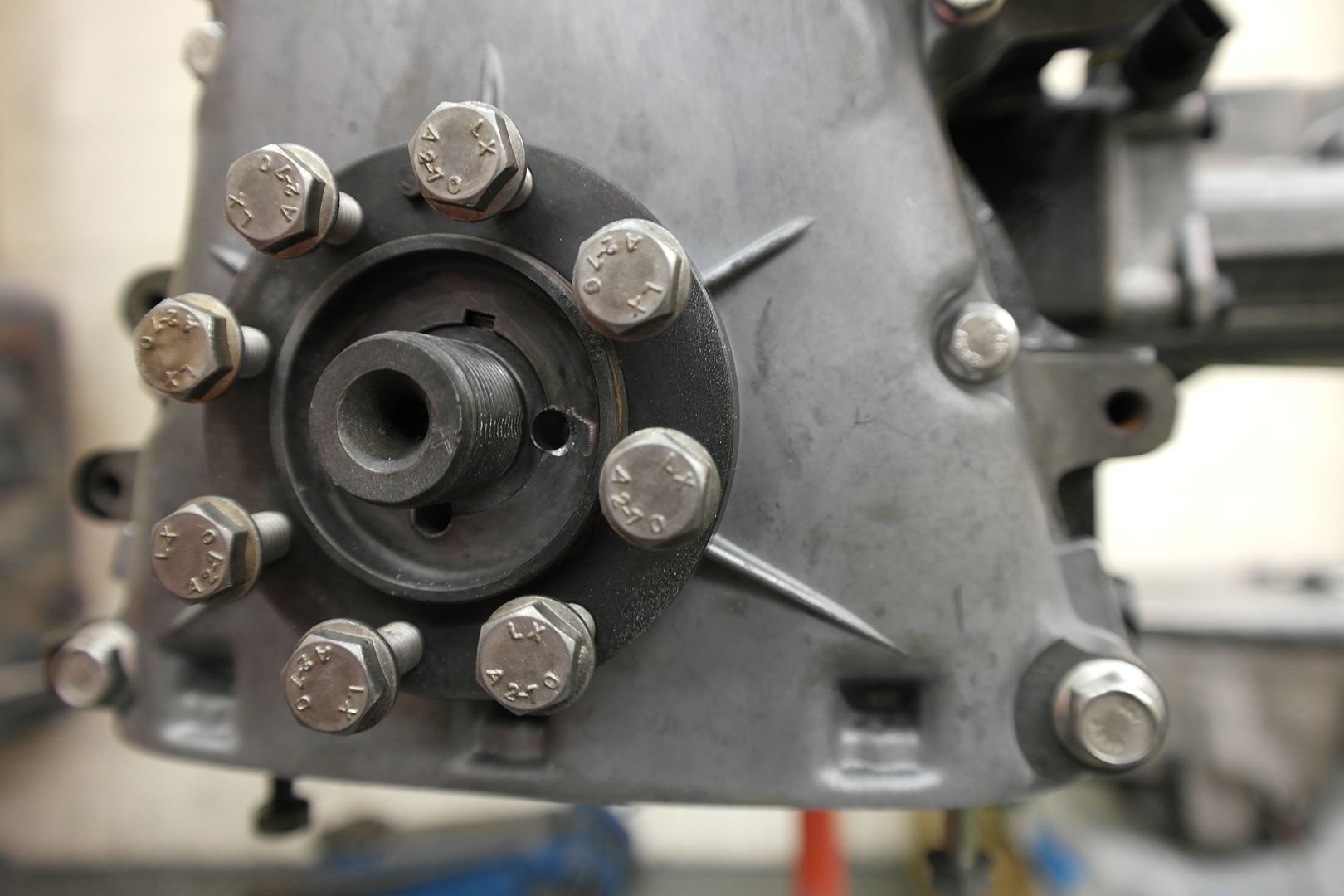

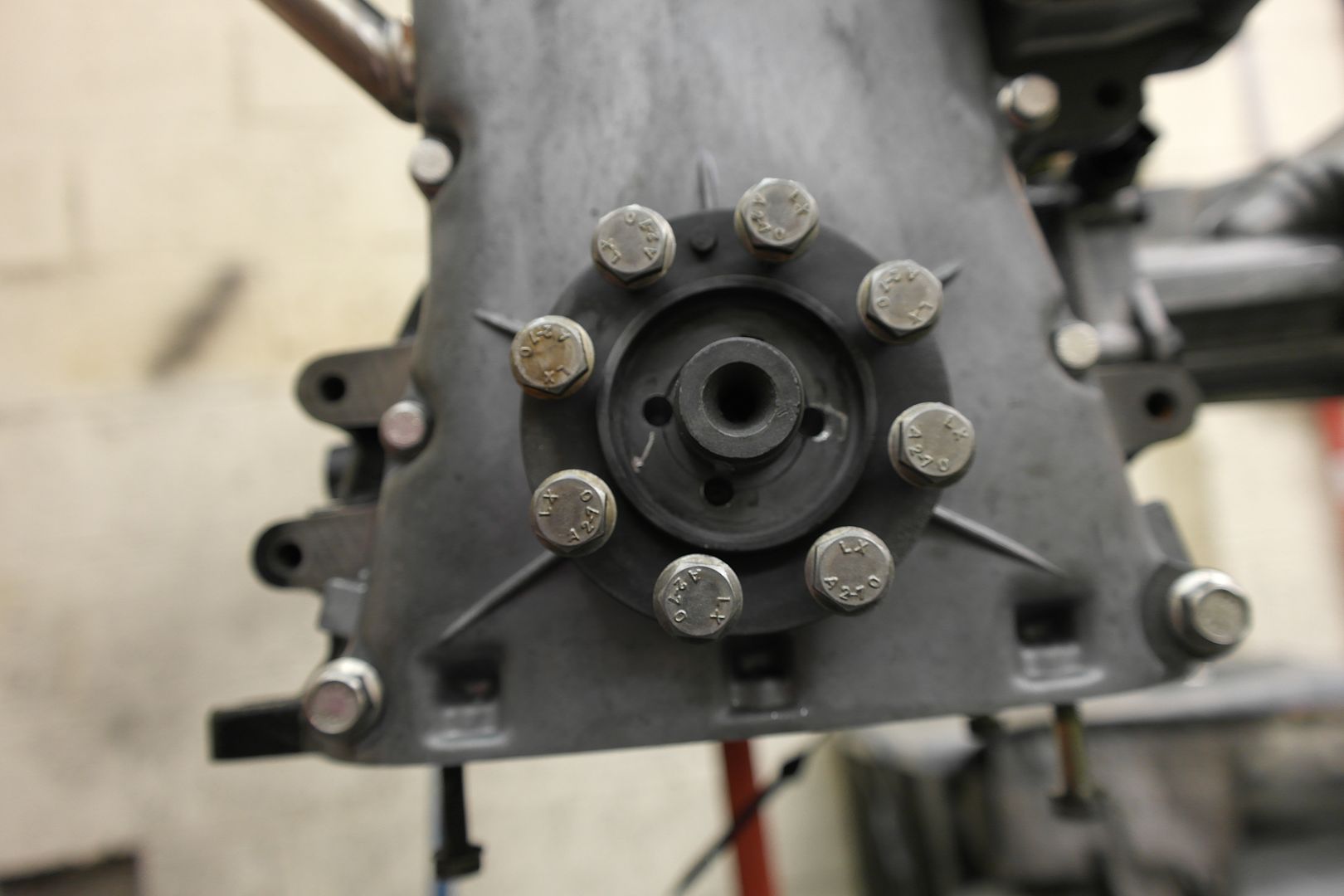

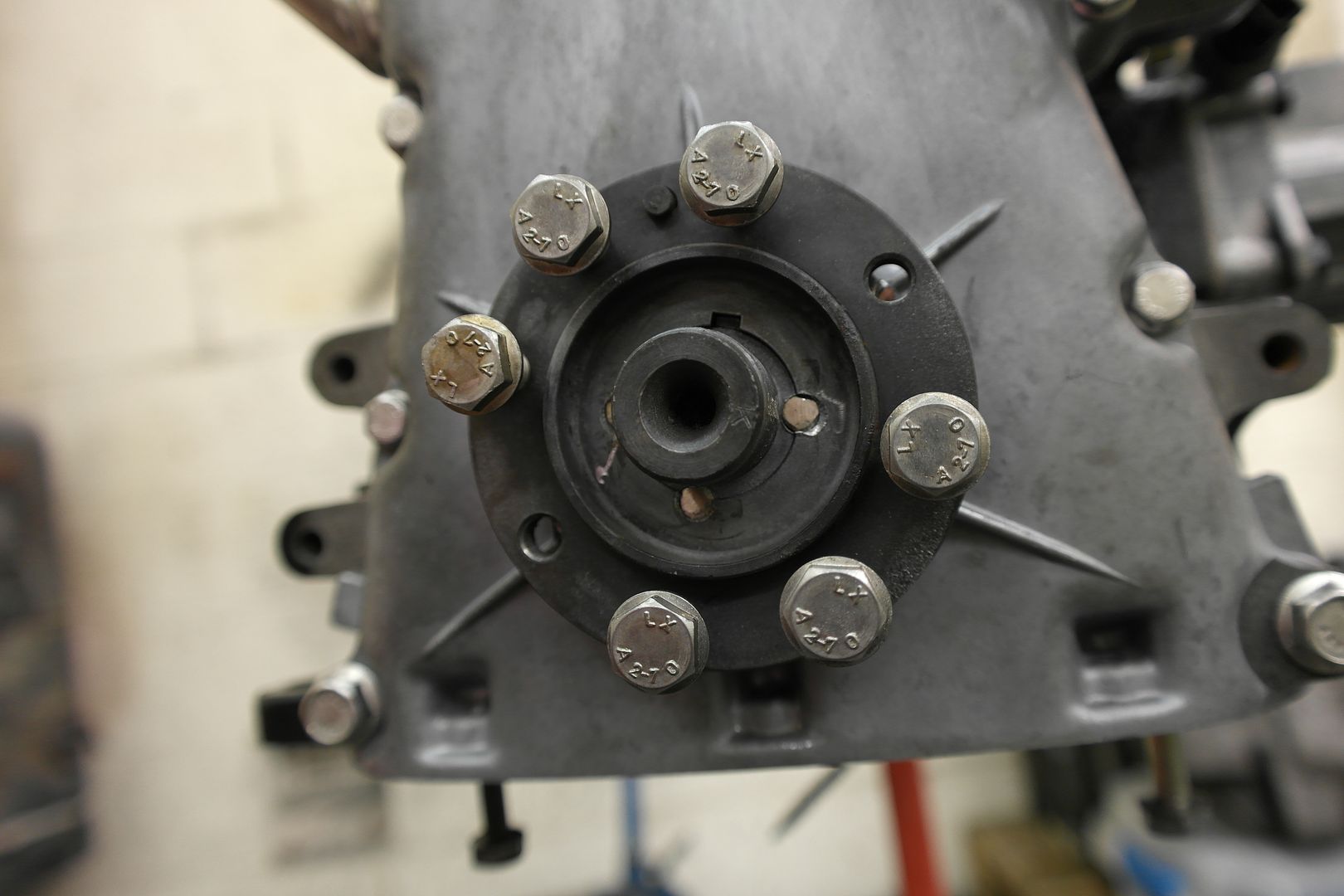

installing aft end cap

and lubed with this

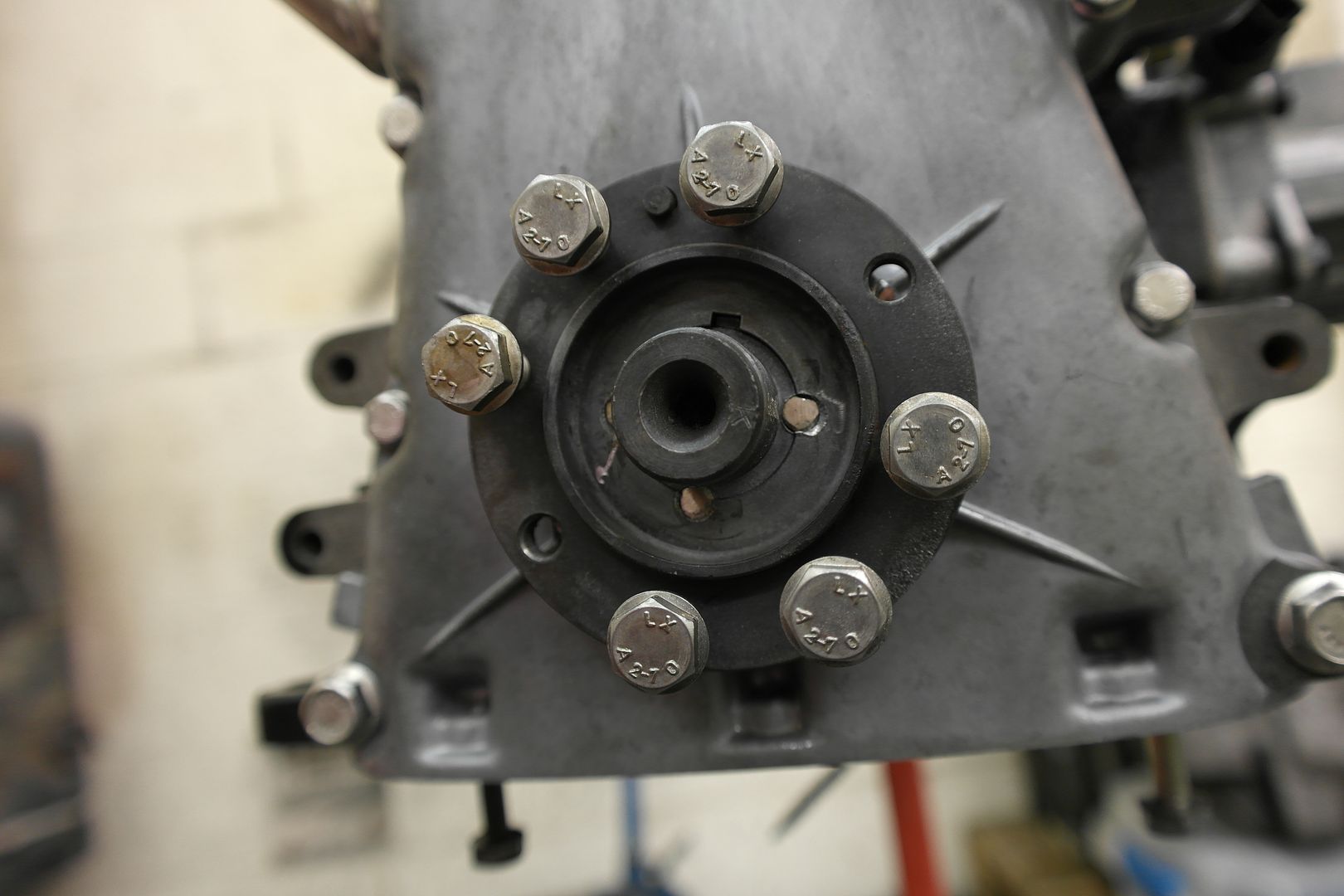

just bought all A2 stainless bolts, they arent that expensive and look good.

all internal parts get RED locktight, all external gets Blue/green locktight.

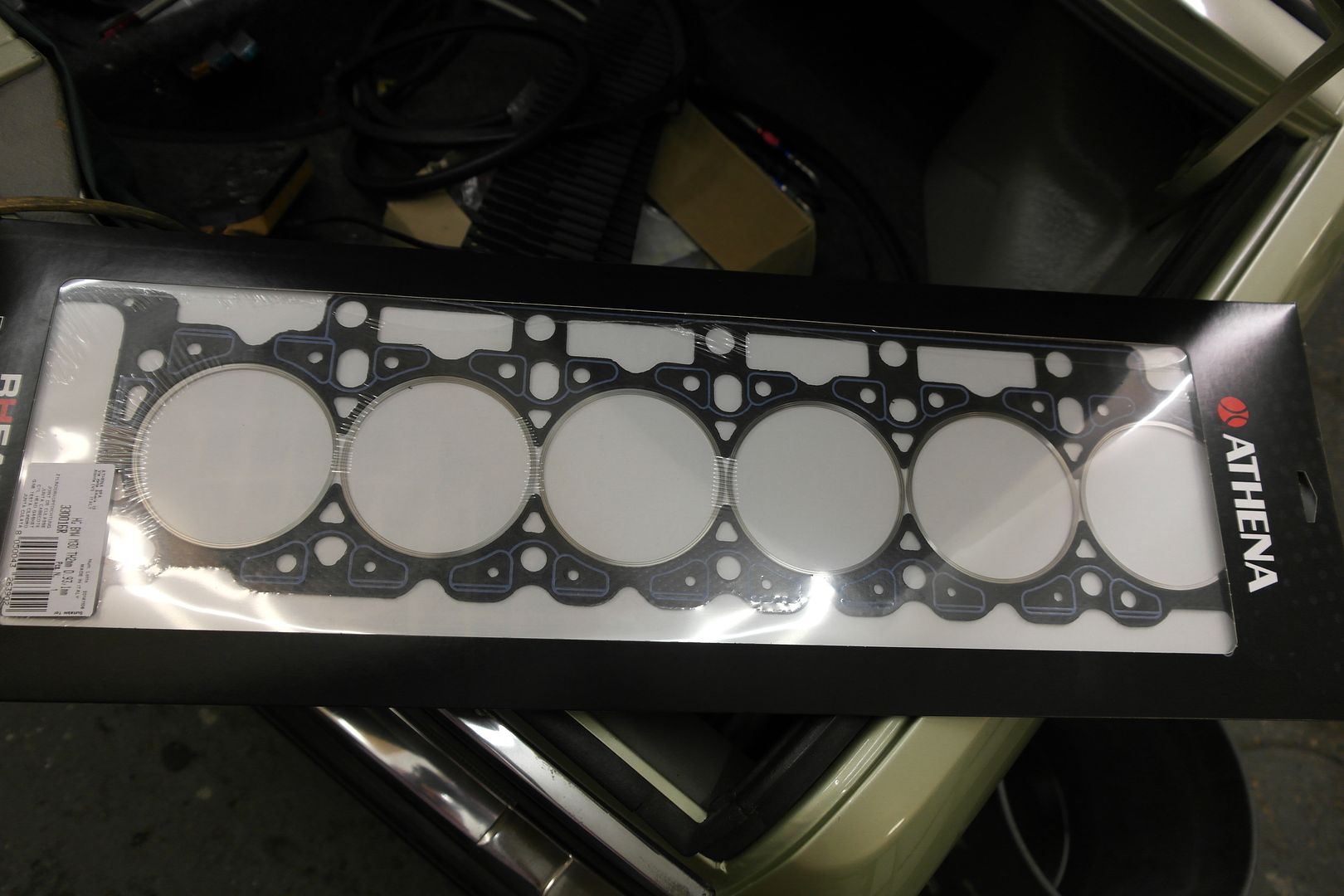

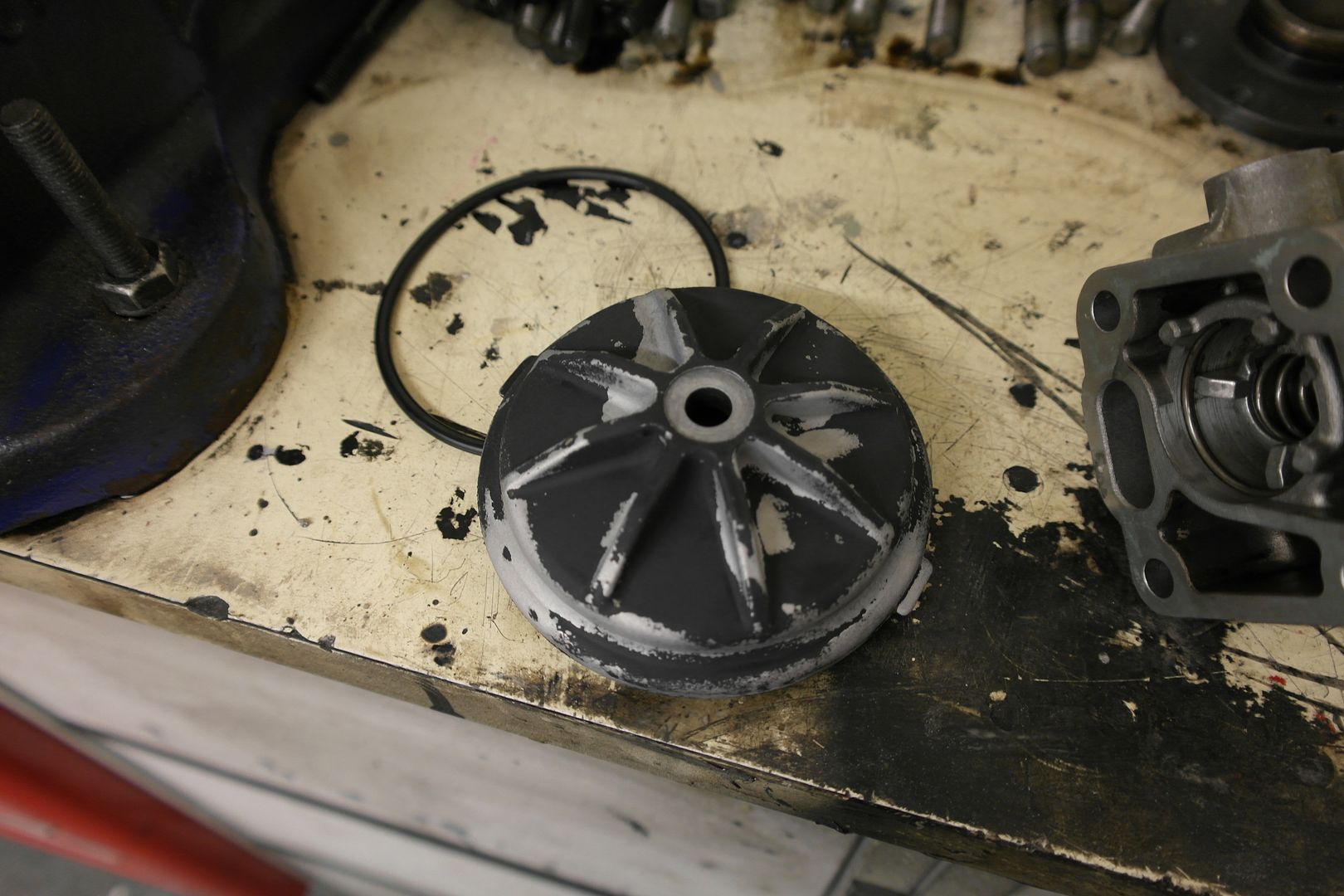

new water pump and refreshed pulley

was going to start balancing the rods

but couldnt get repetitions of weight even within 5g using method above. I though crappy ebay scales, so checked all wrist pins and full rods, each repeated within 0.1g each time, so must be my method. will need to look into it.

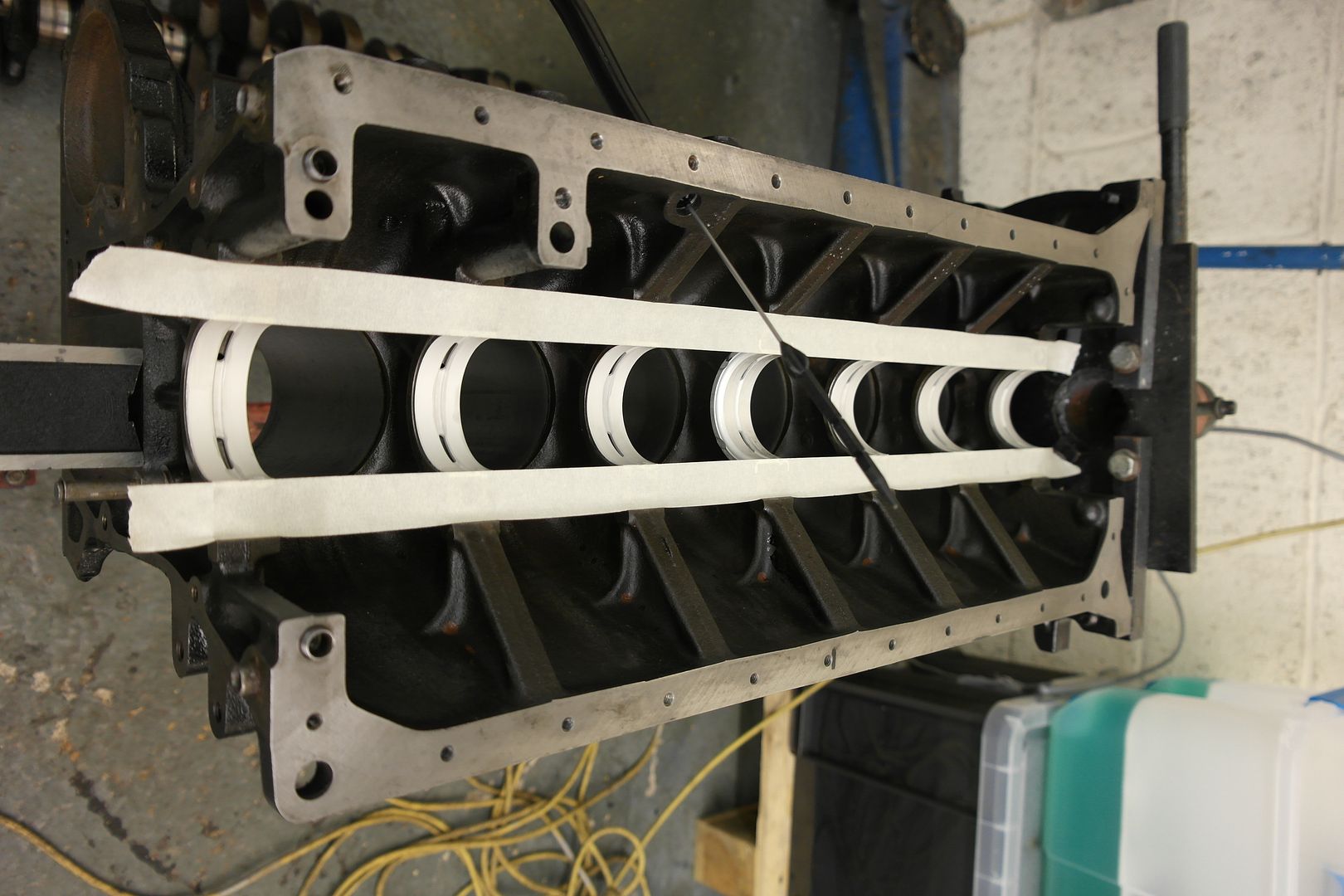

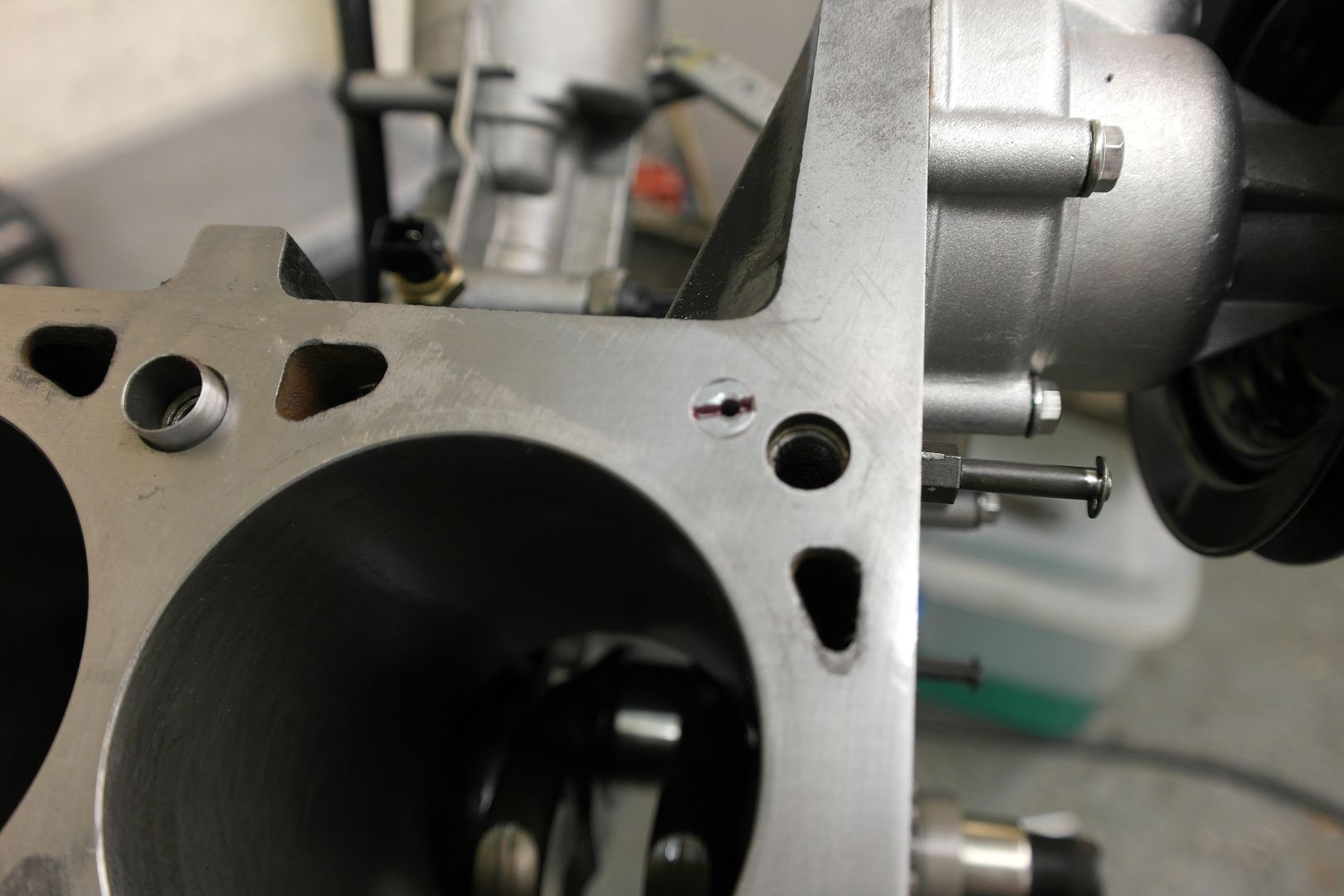

installed other end cap, turbo drain & chain and tensioner/guides

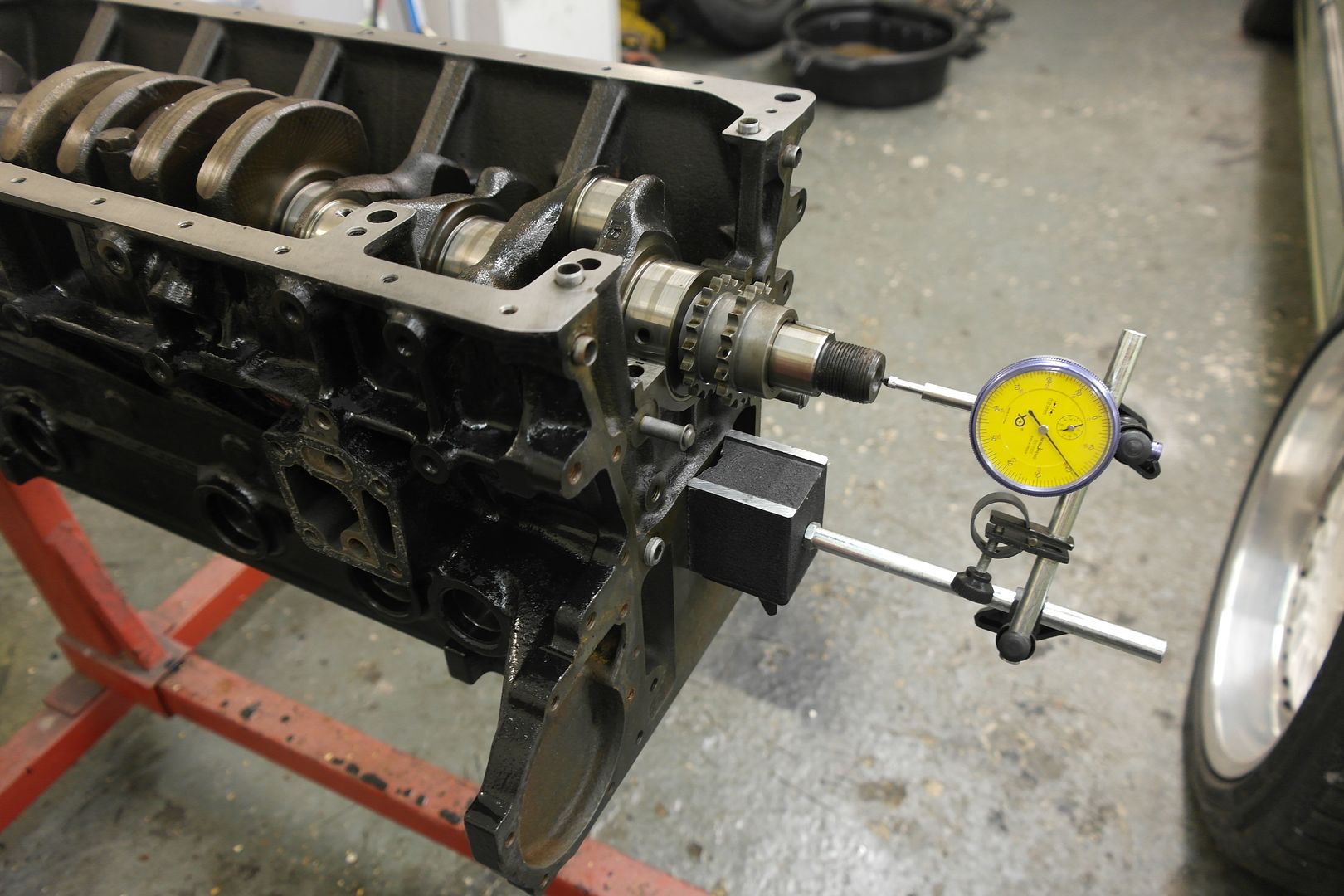

6mm dowel keys

drilled Crank and pulley 19mm deep

installed dowels to length

this seams to be a common mod on the PPF Forum as a must for any engine build. Normally 1 dowel is enough, but i though 3 is better.

No locktight used as i may want to remove in the future, plus all torque is radial so the B&%$£$D nut is enough to hold the non tapered shaft in place.

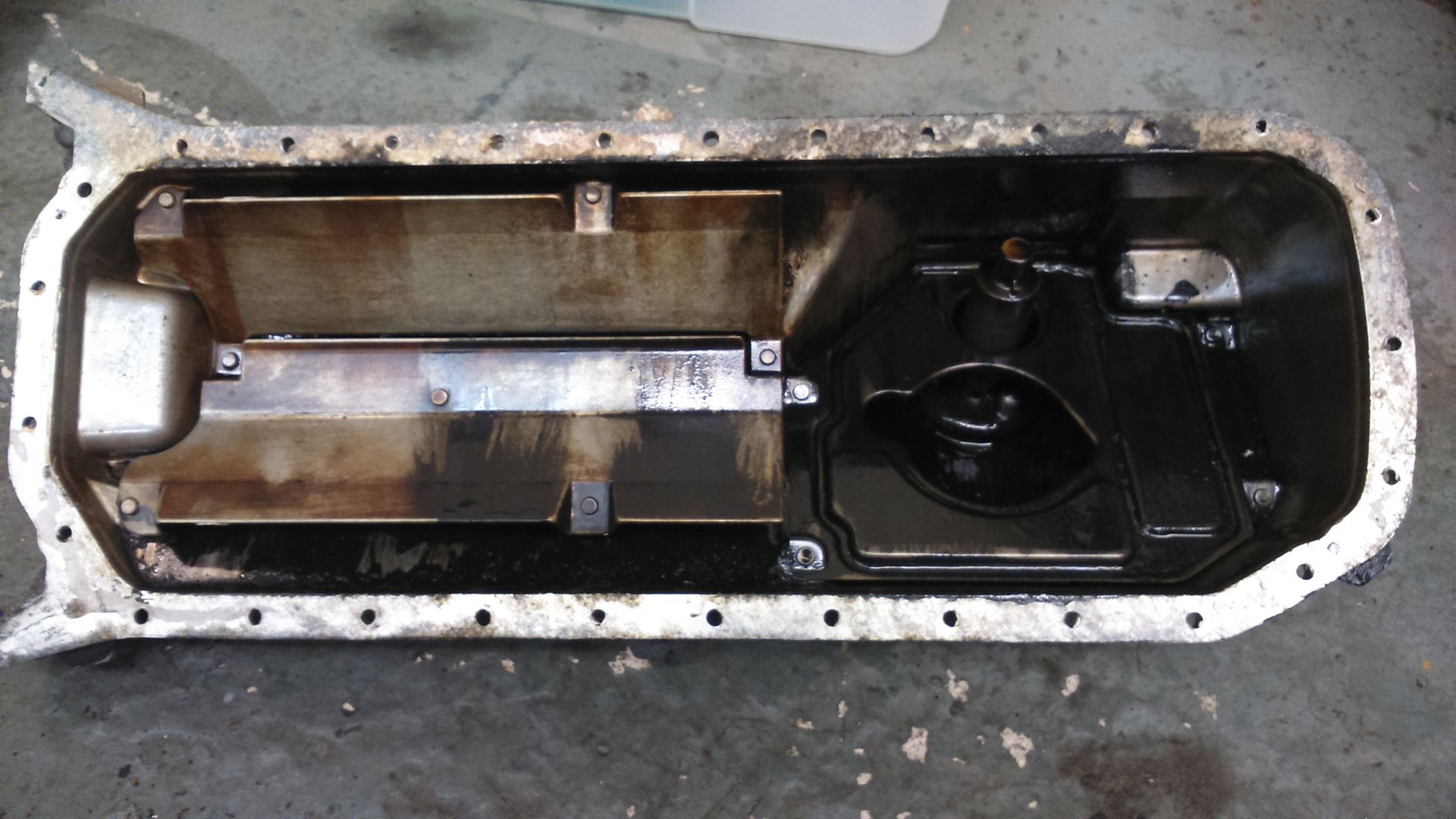

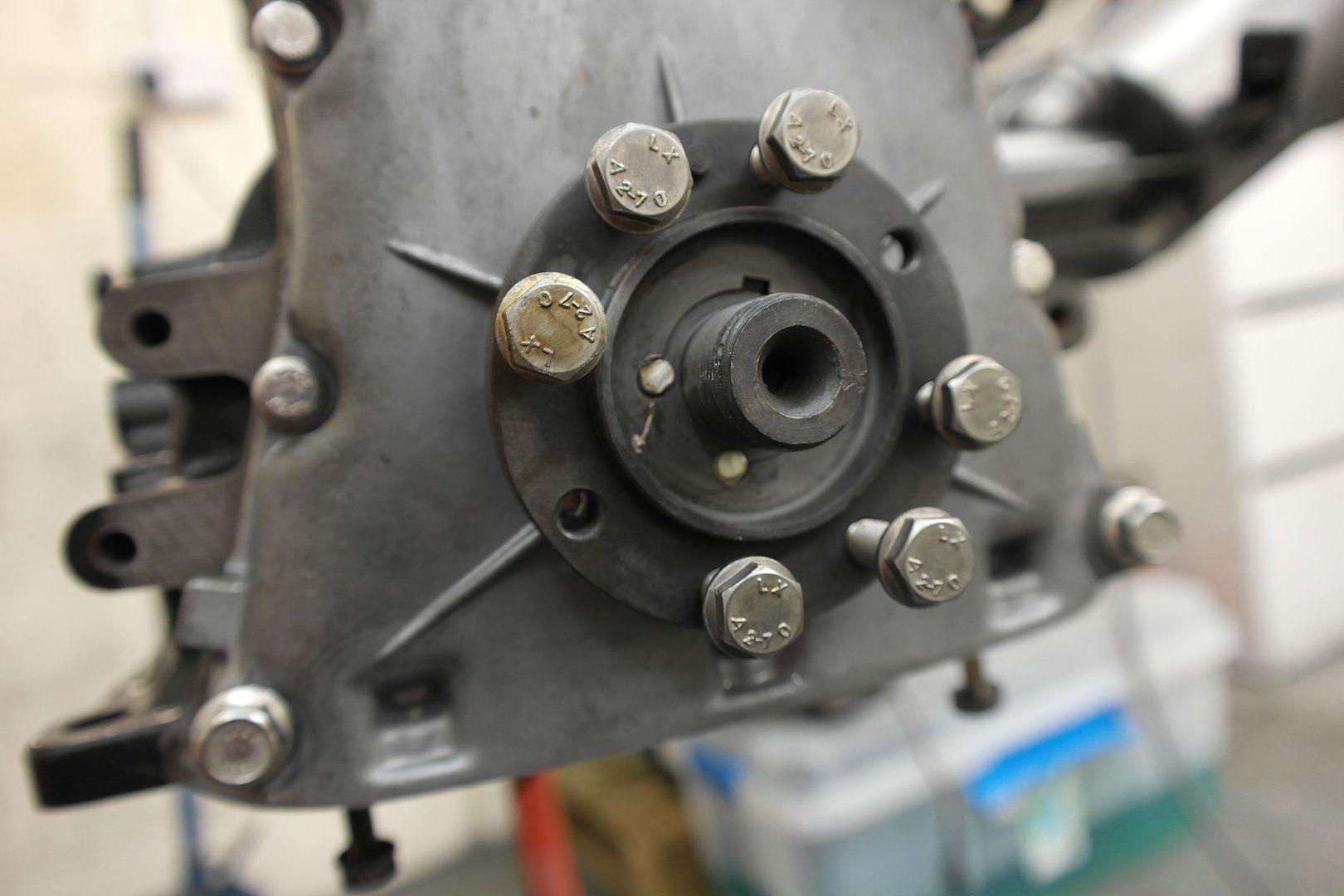

Another reason is the 26 year old oil pump is now NLA or silly money if available, the Gears are all sold out, so options are, run the old pump, or try my hand at Dry sump conversion.

A Weaver 4 stage pump is on its way.

3 scavange 1 supply, plan is a billet adapter to oem oil supply, that will tie in the oem filter canister and thermostat oil cooler.