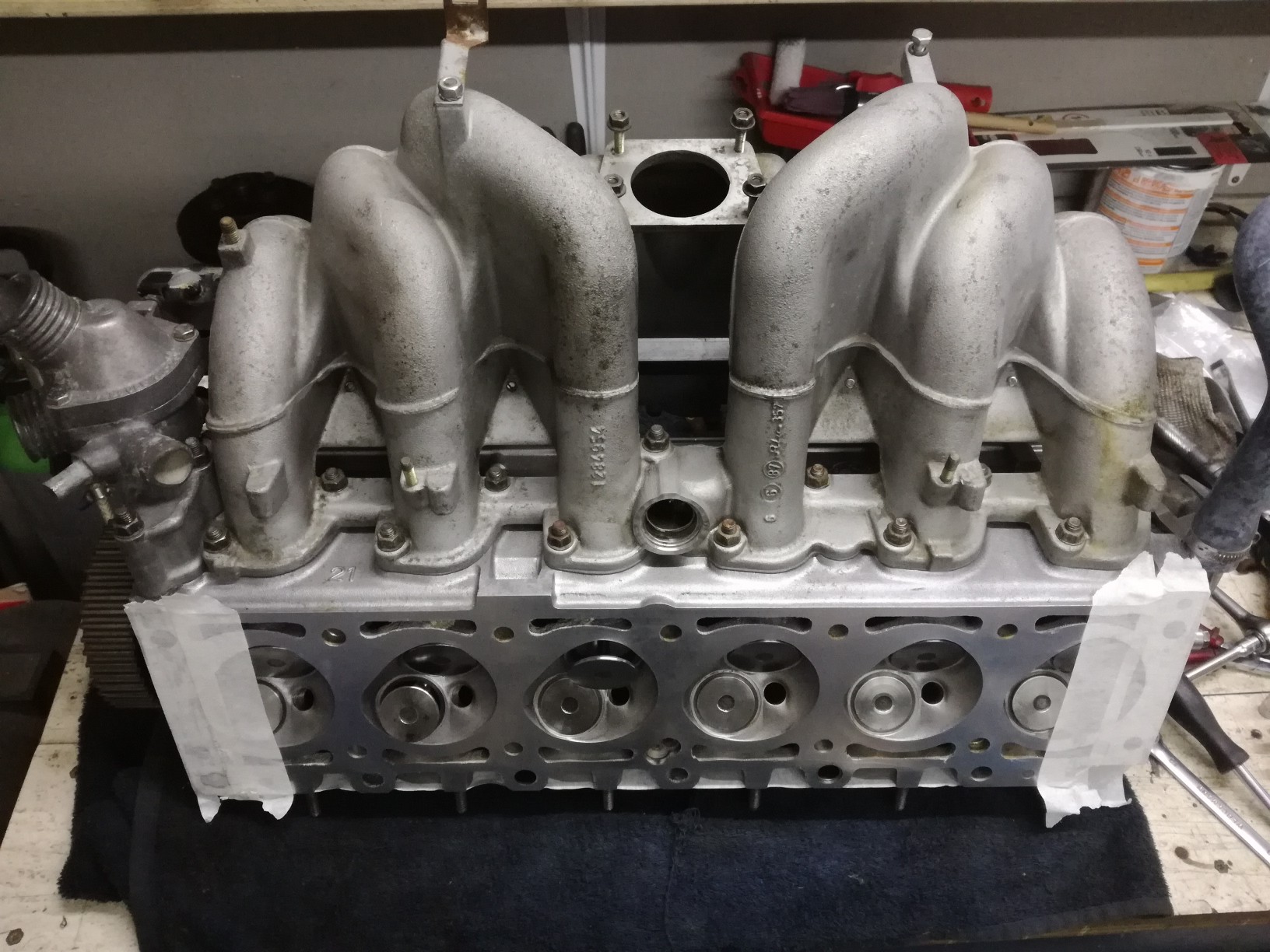

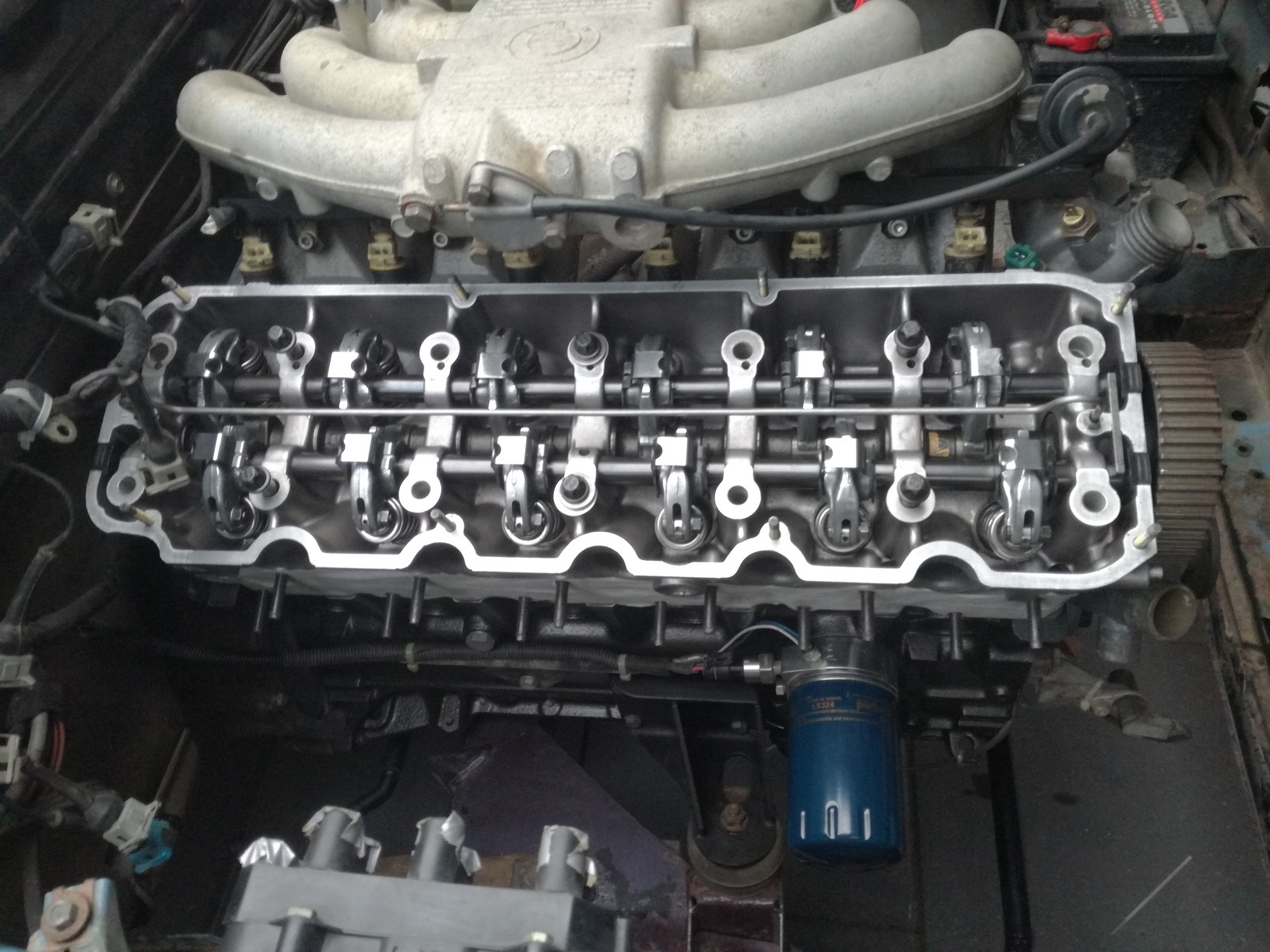

Time to put an engine together with these parts

Over time i gathered lots of new components like gaskets, oil rings, piston rings and bearing shells.

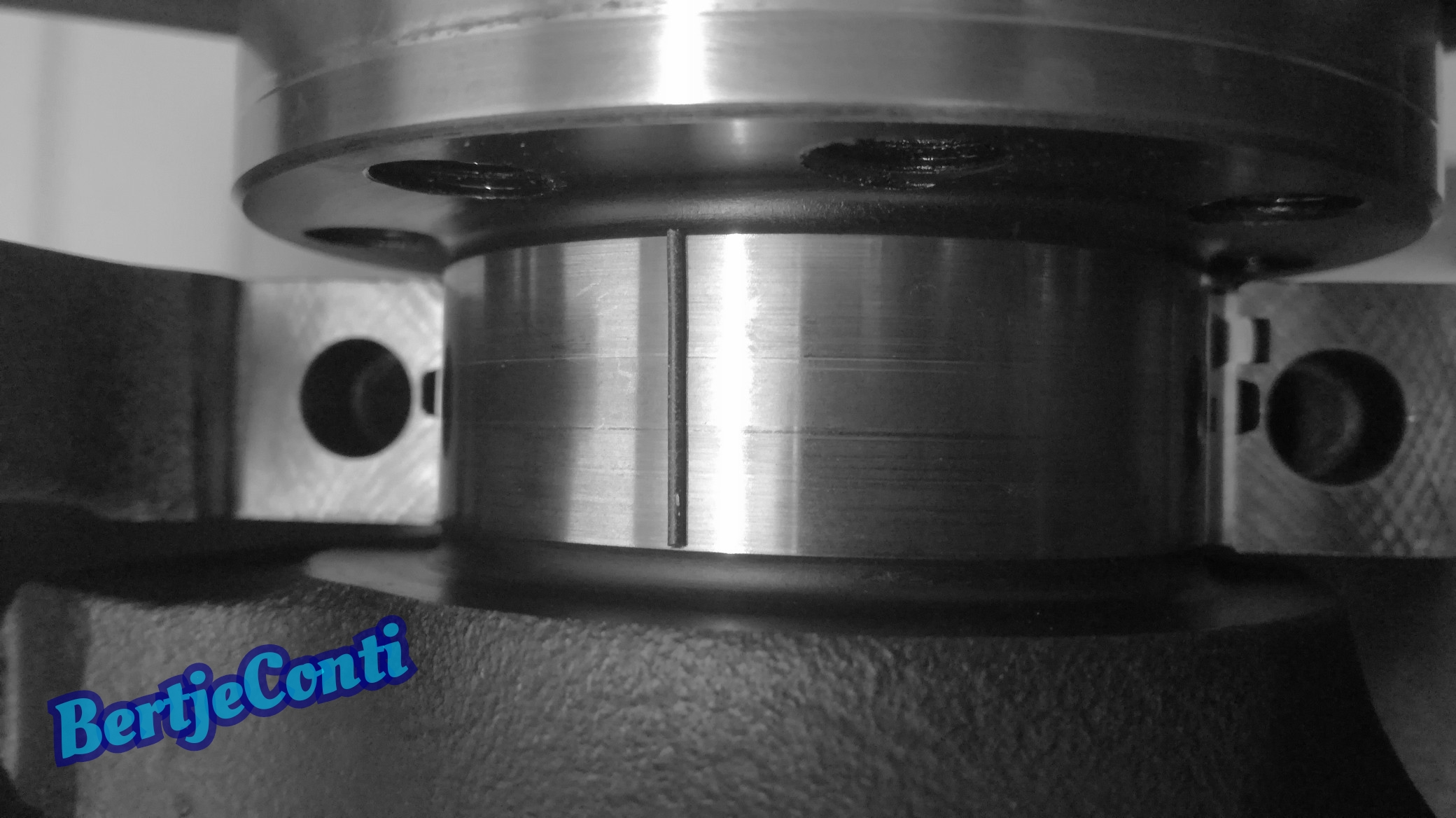

Crankshaft and camshaft from this motor are in excellent condition, no rework needed. Nice, standard bearings shells will be used.

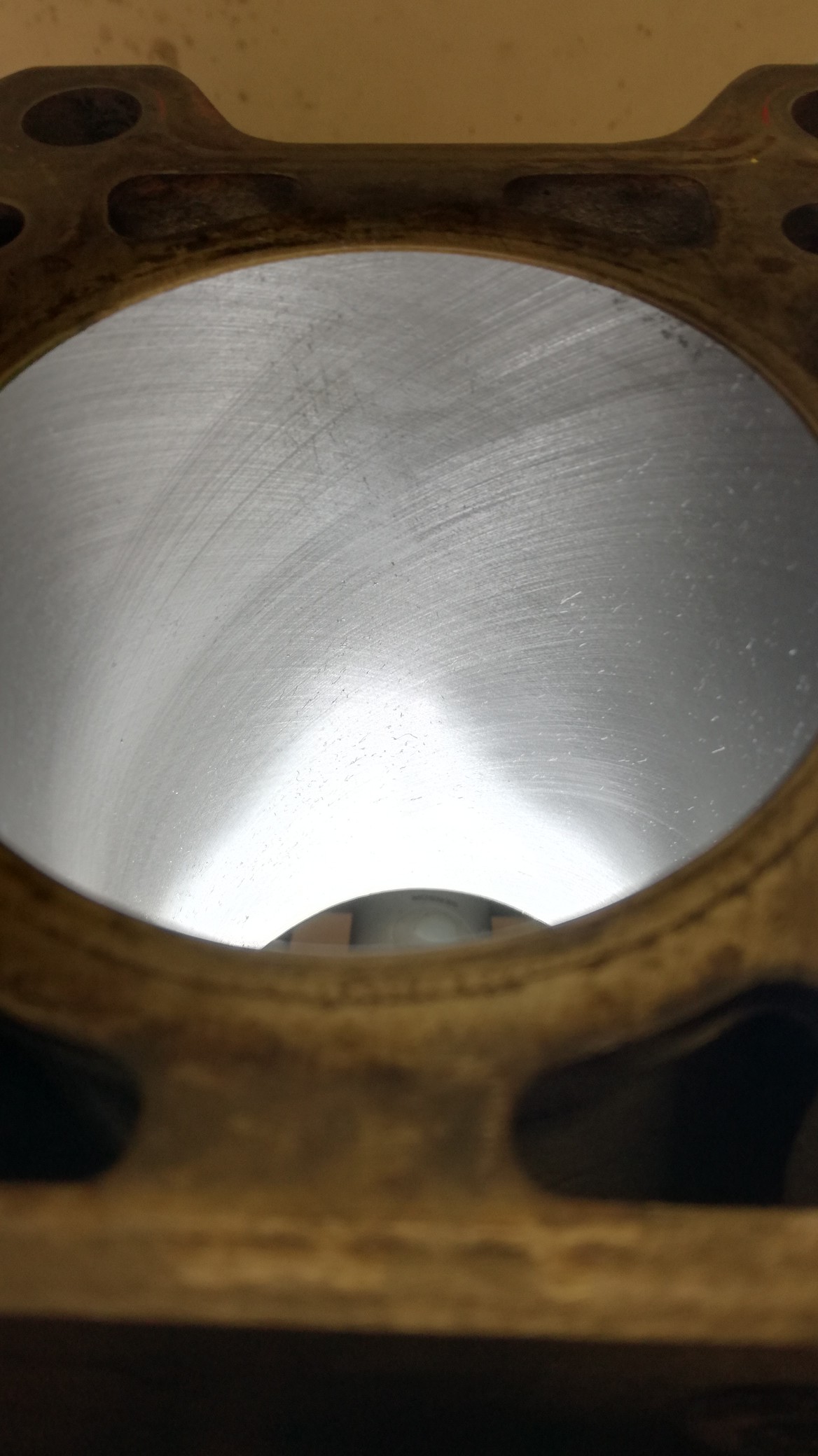

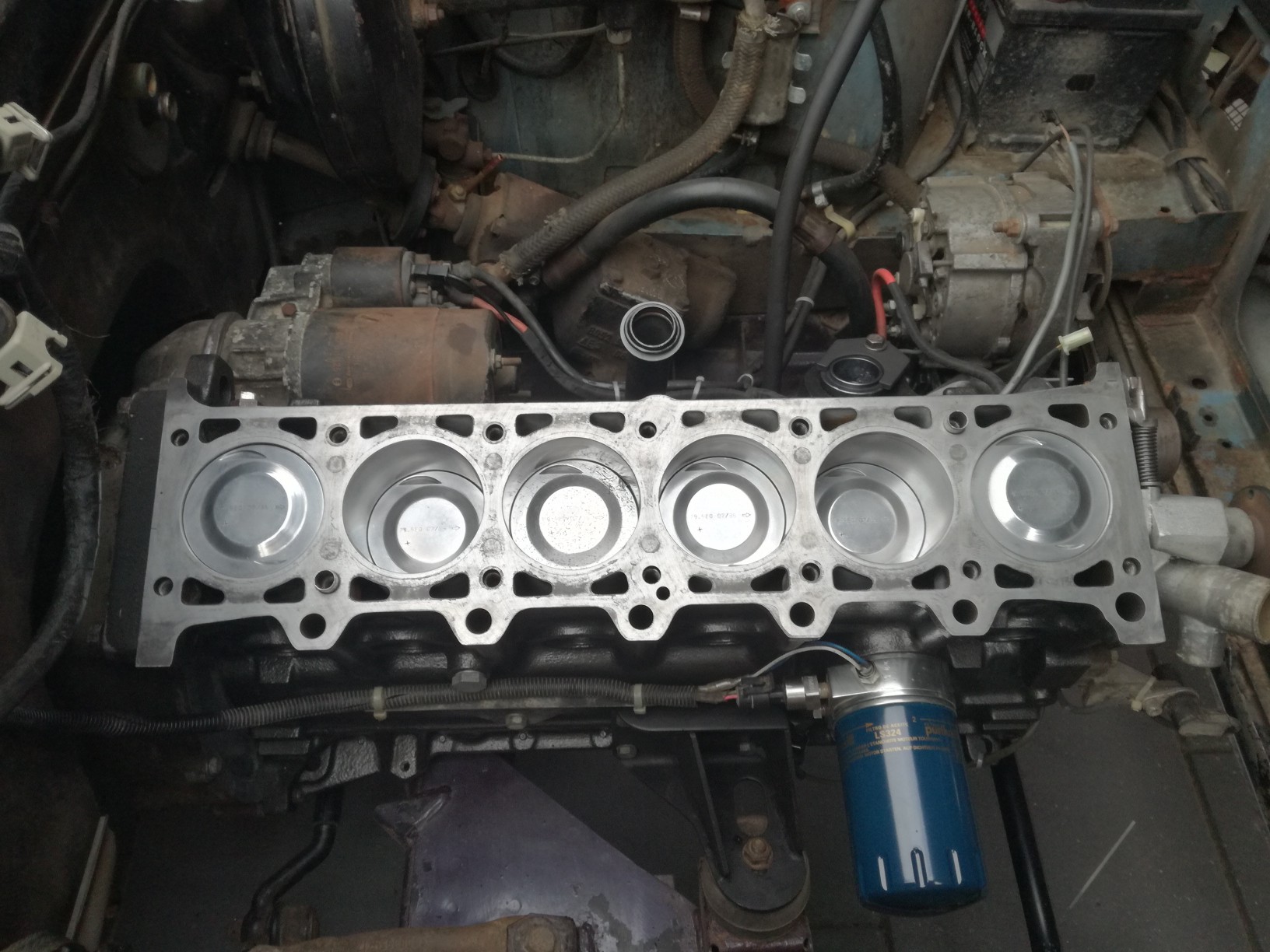

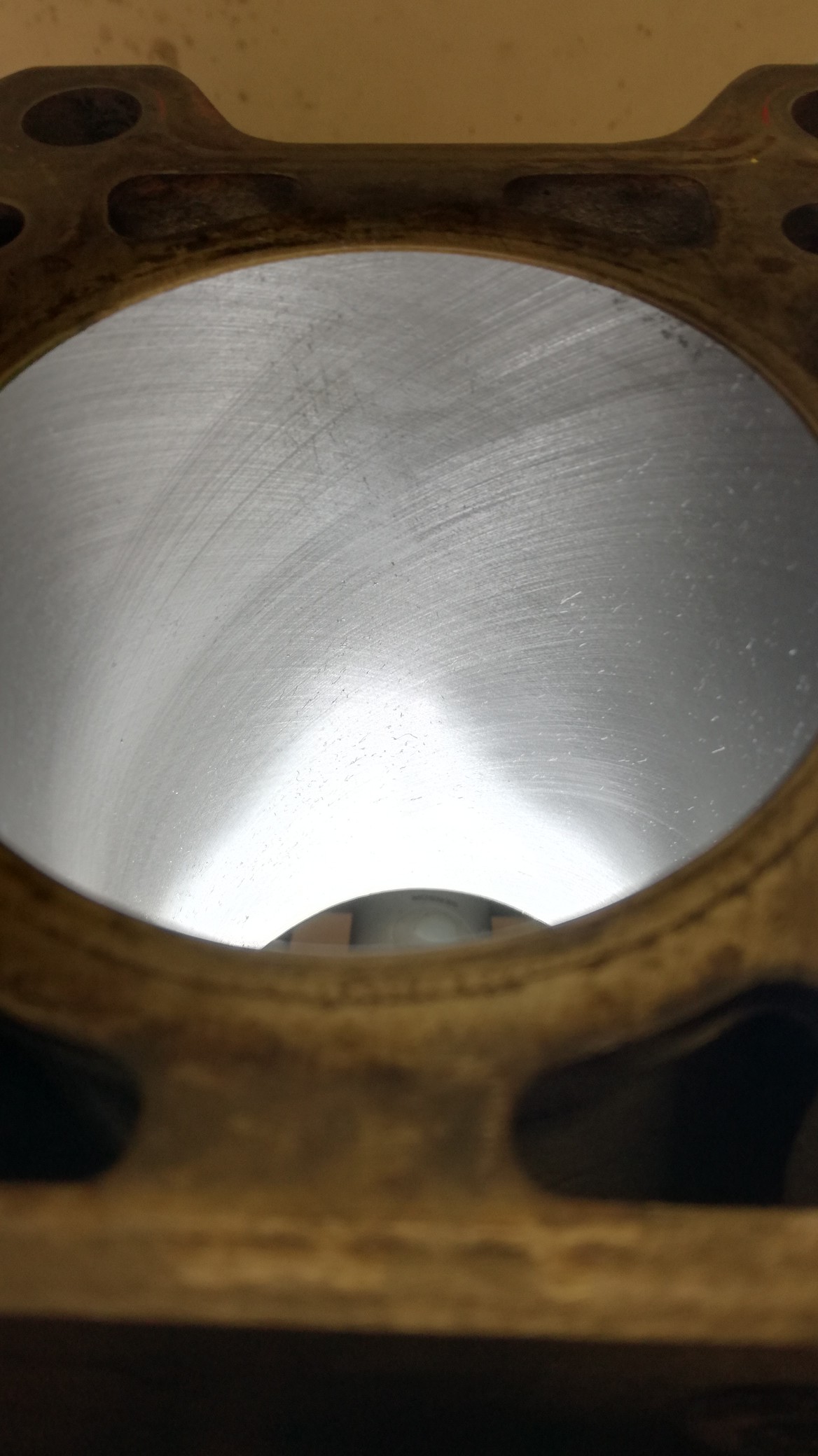

The block went to the machine shop, only for an light hone, so the standard size pistons could be used with standard piston rings.

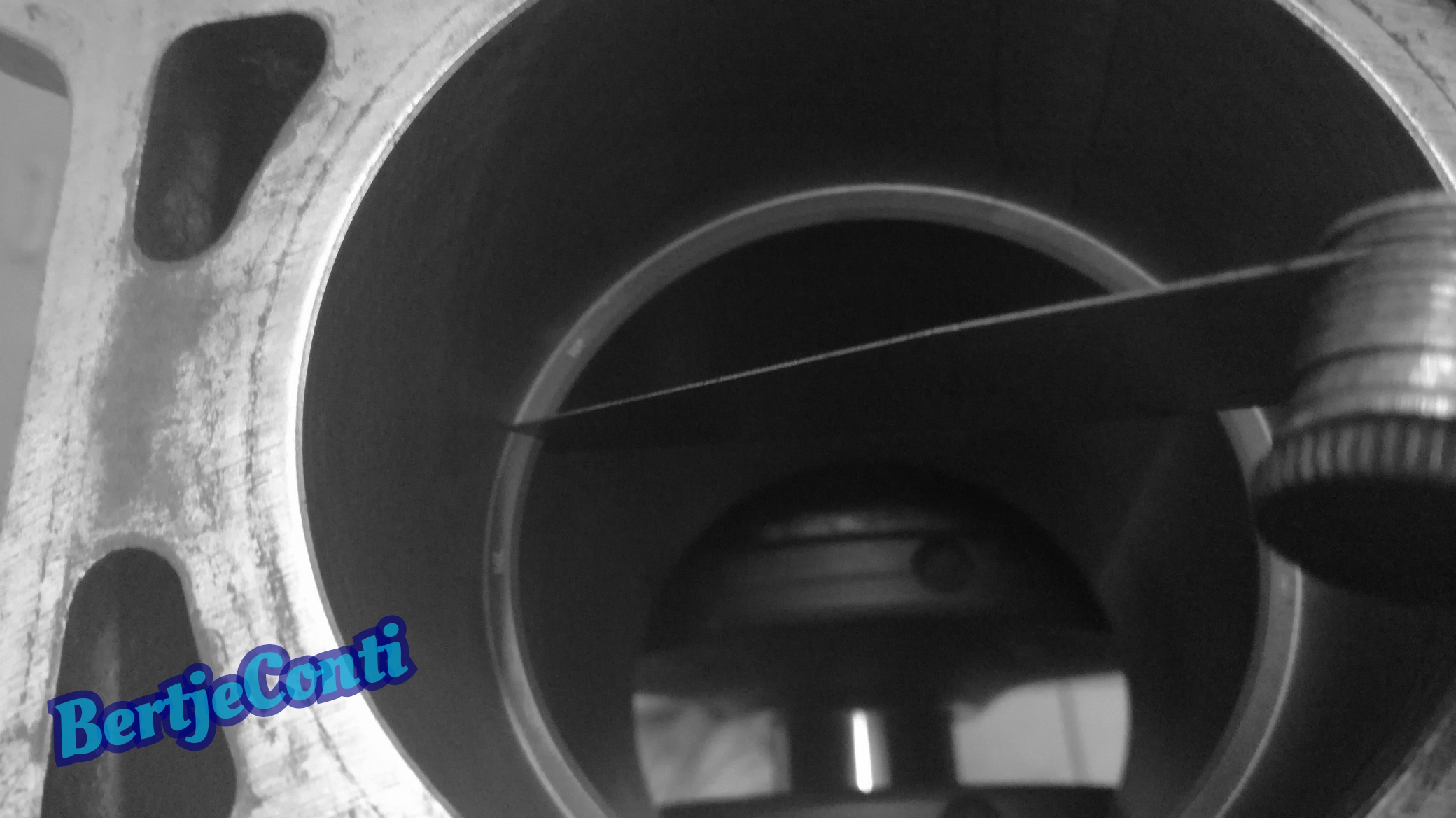

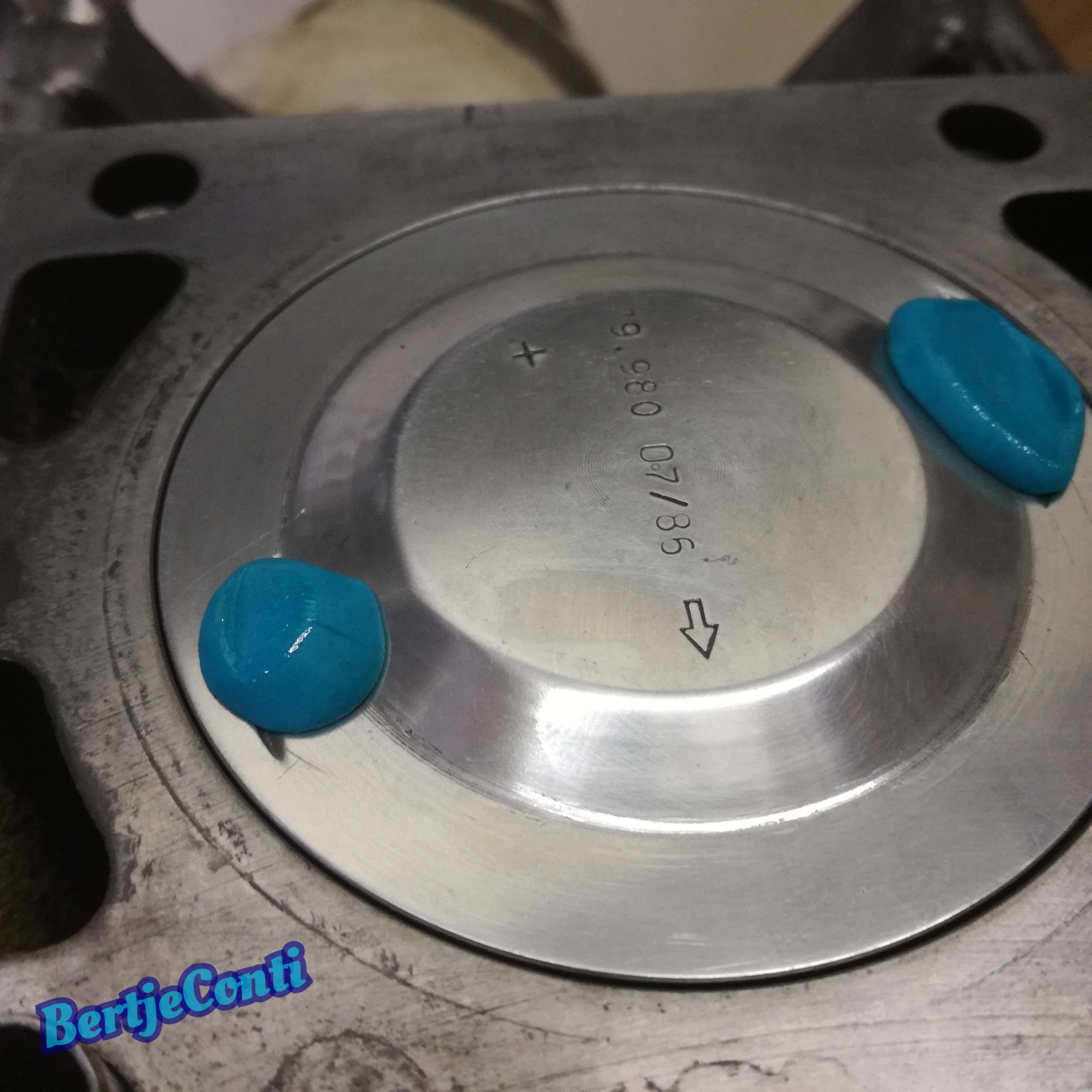

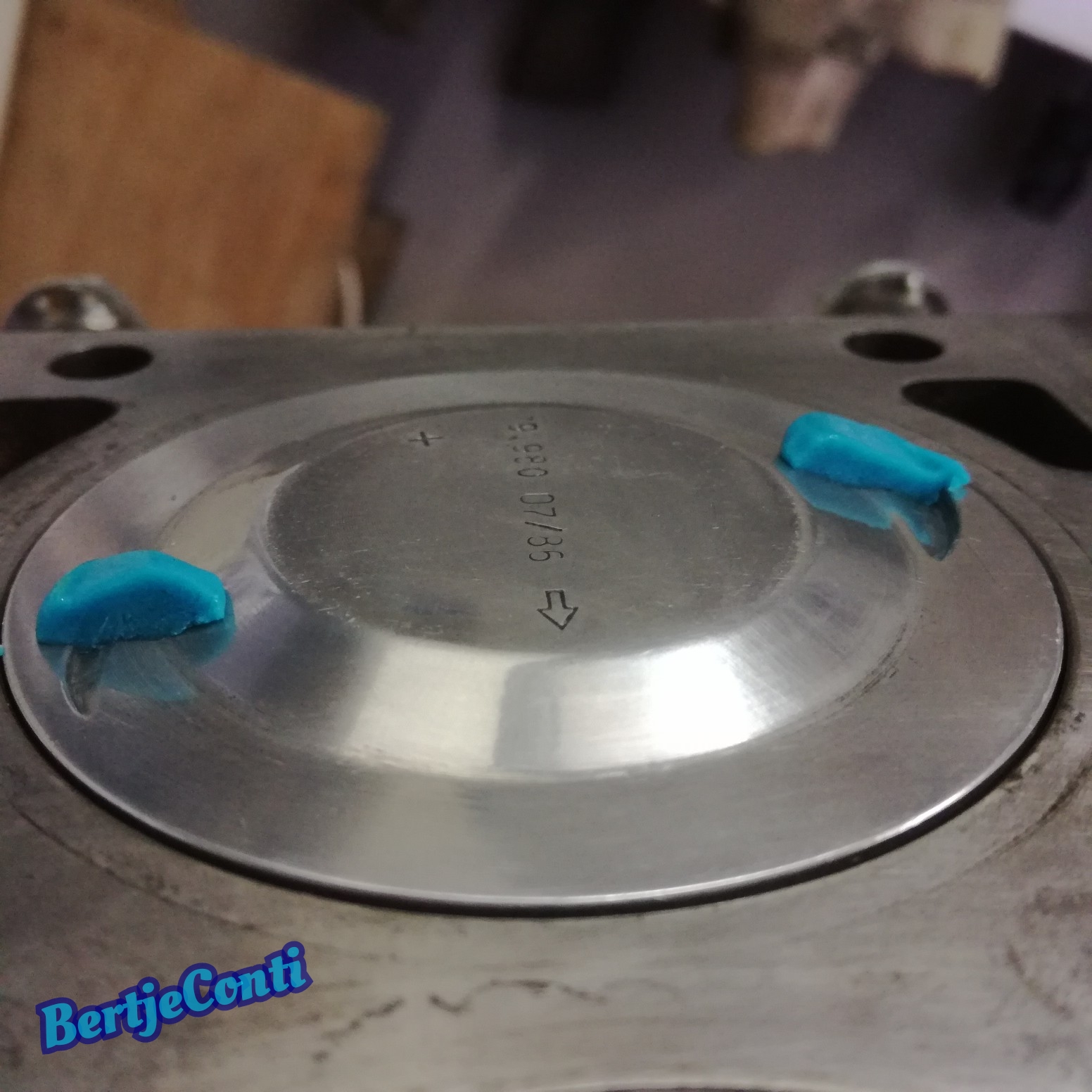

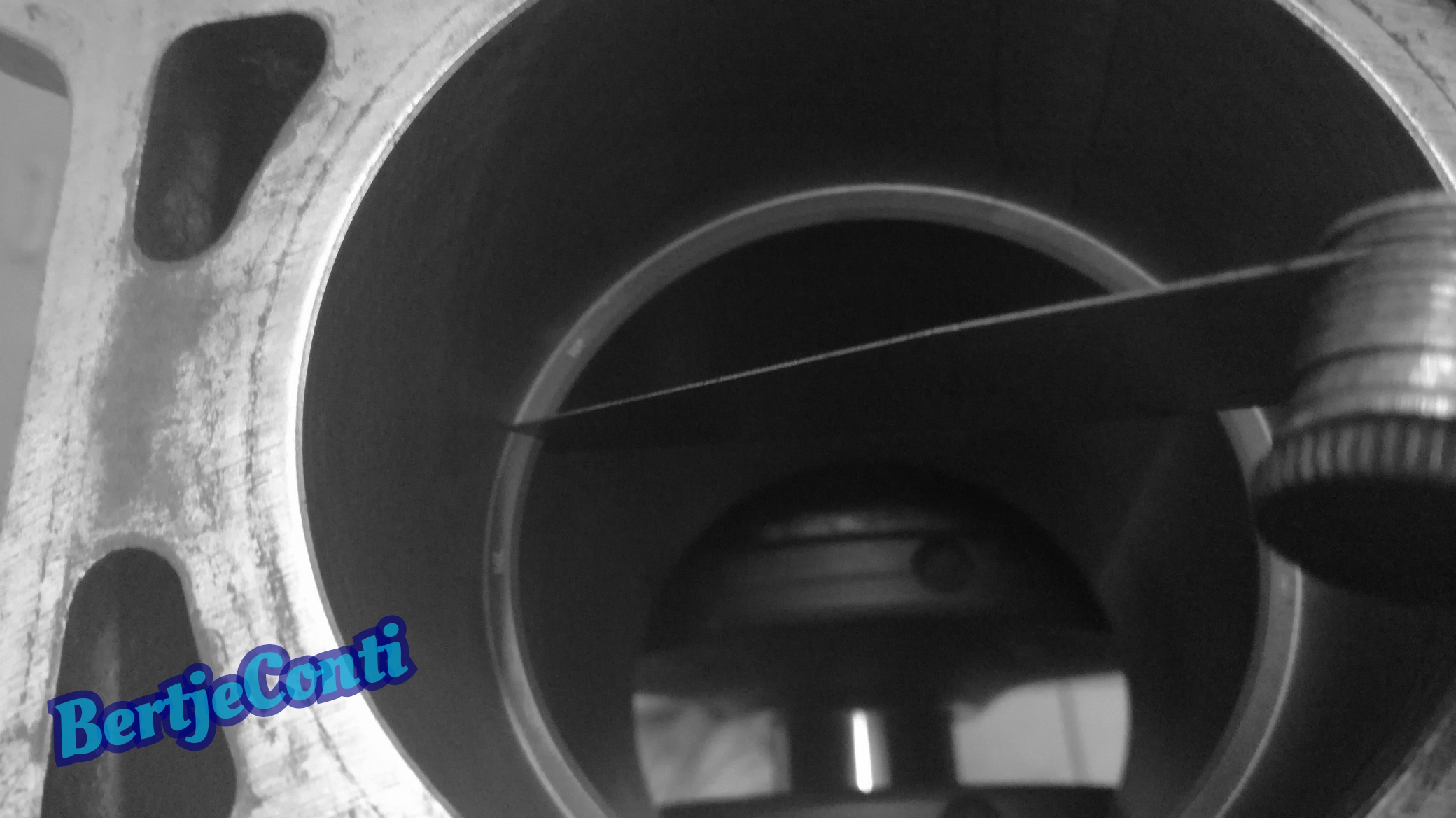

a before and after shot from a cylinder bore:

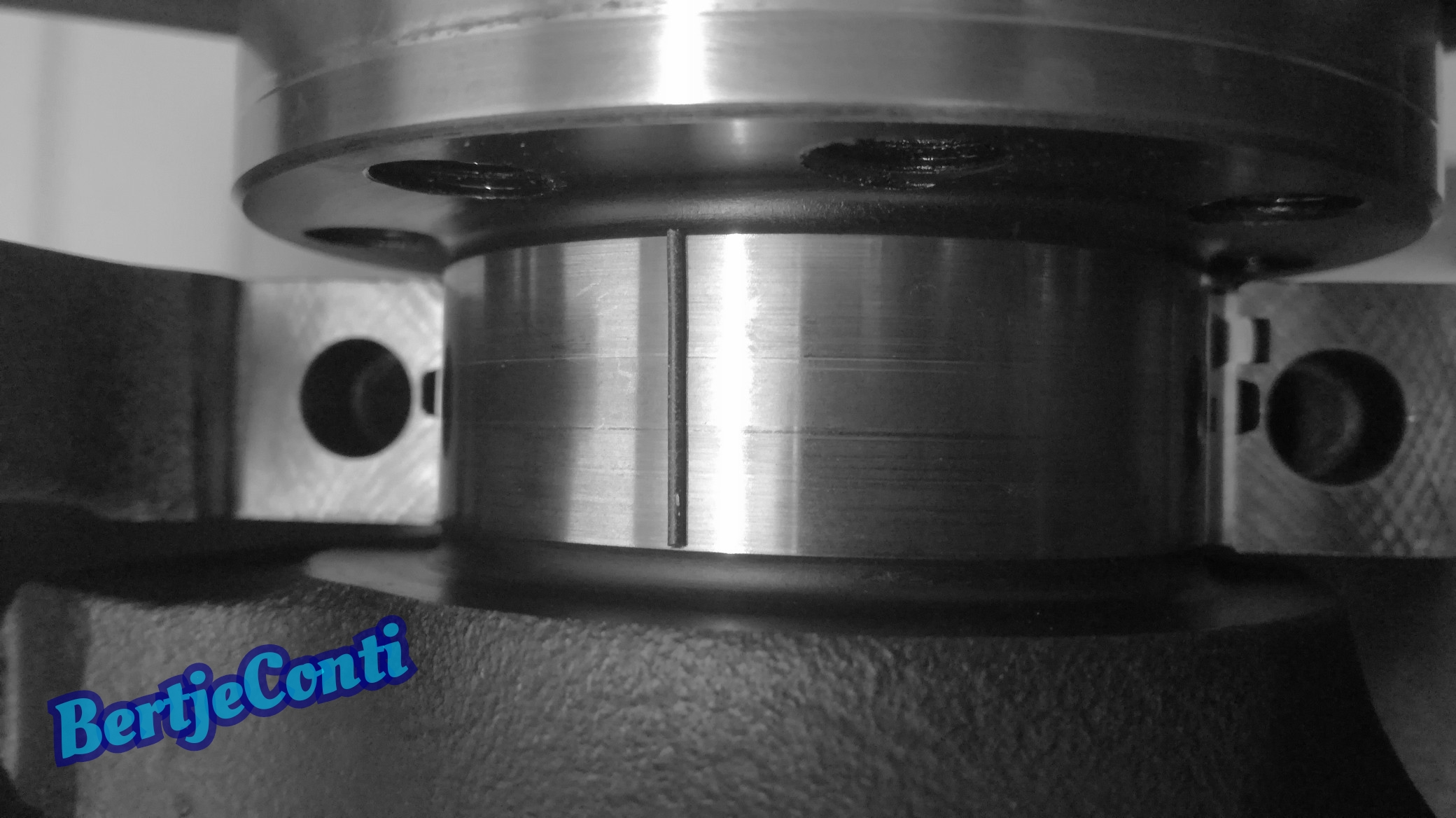

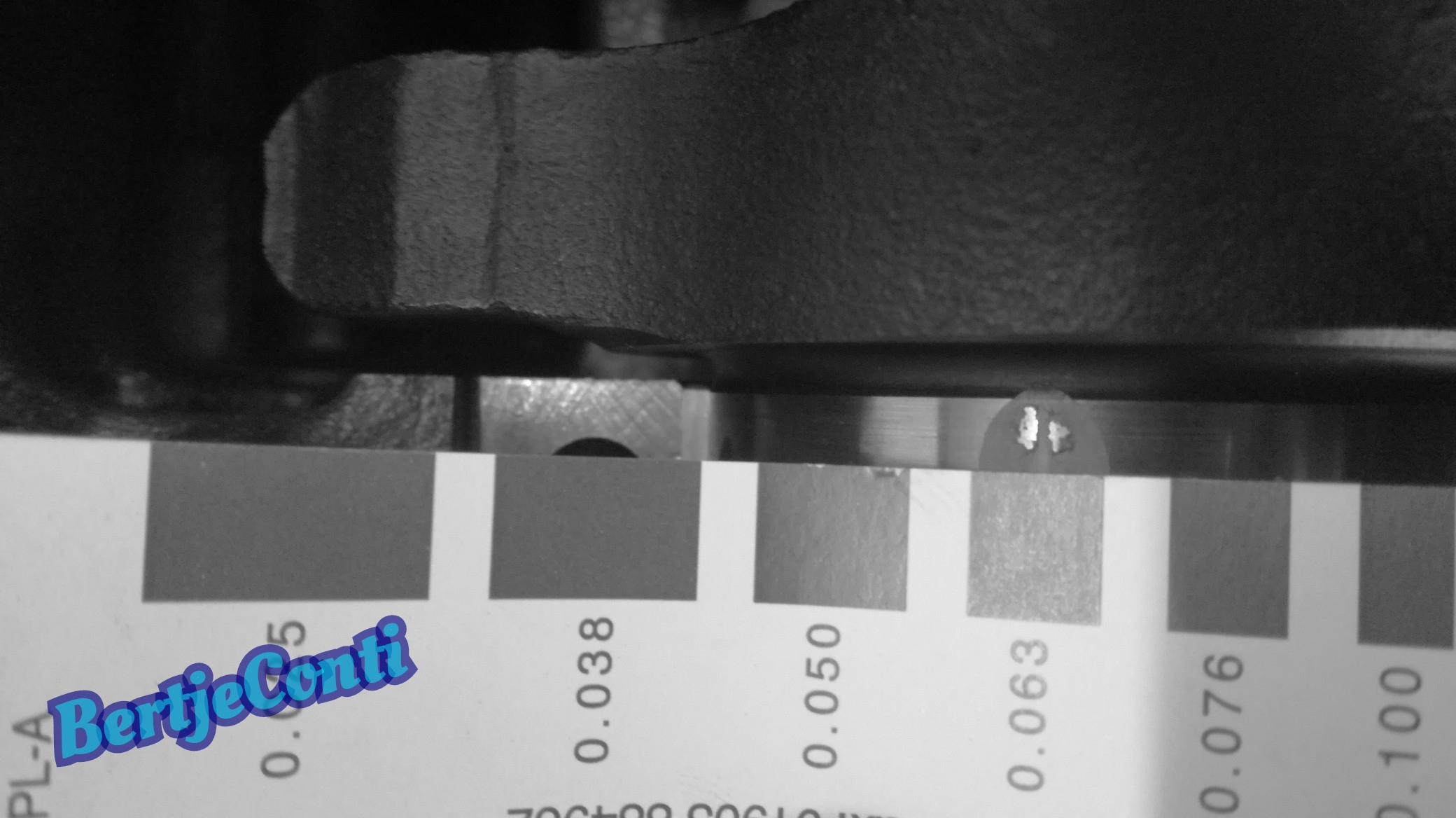

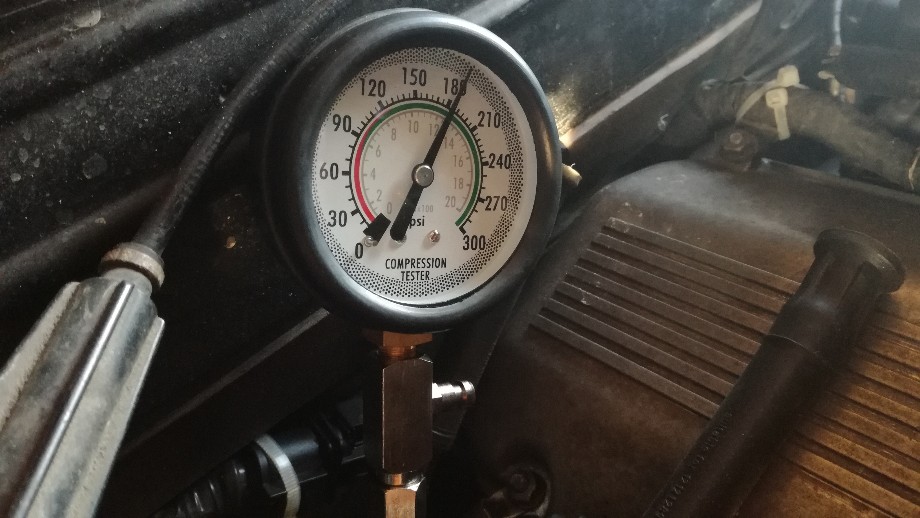

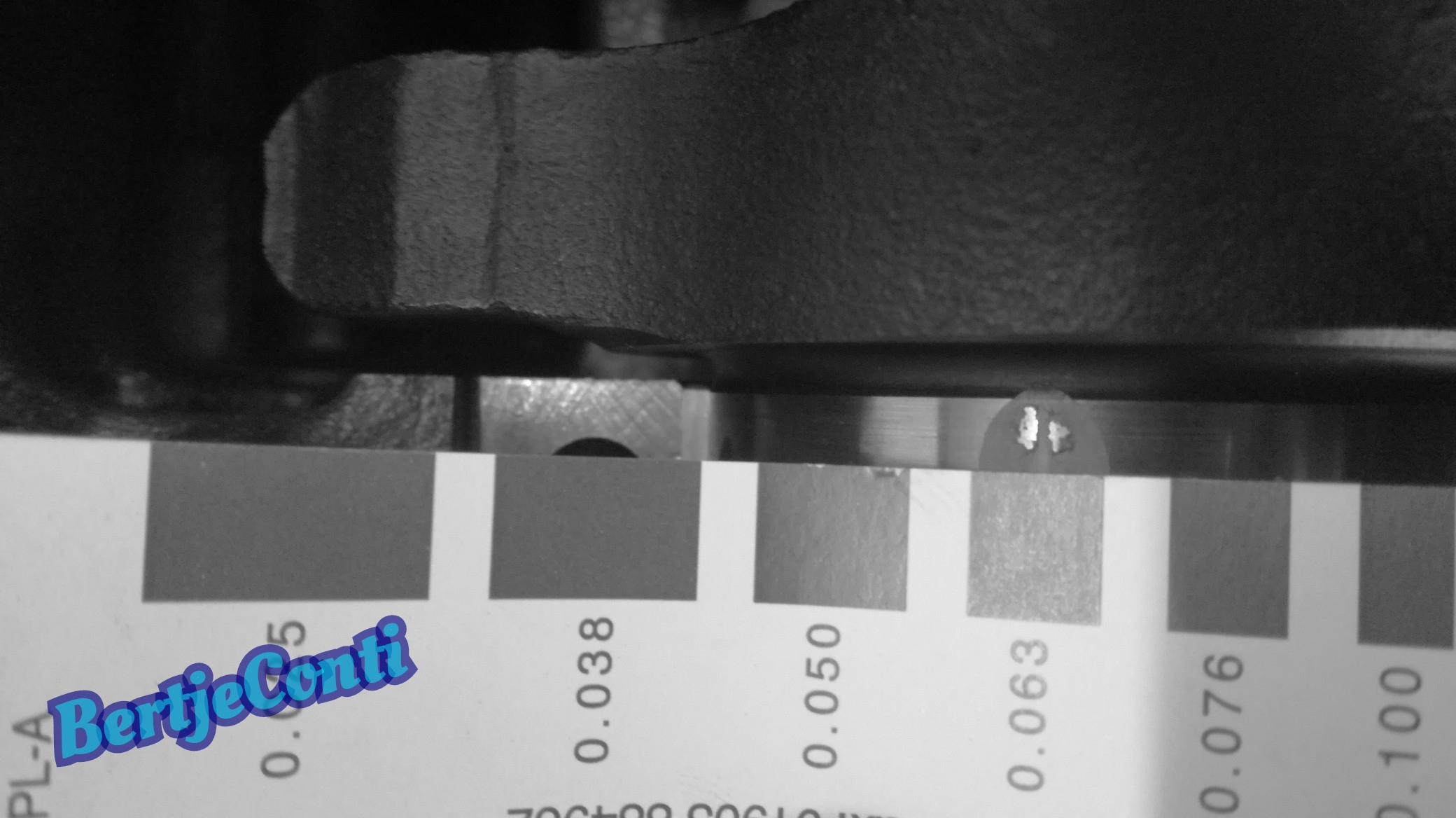

before reassembing i tested the main bearing clearence with plastigauge on different bearings:

Main bearing clearance is 0.06mm which is within specs for this motor:

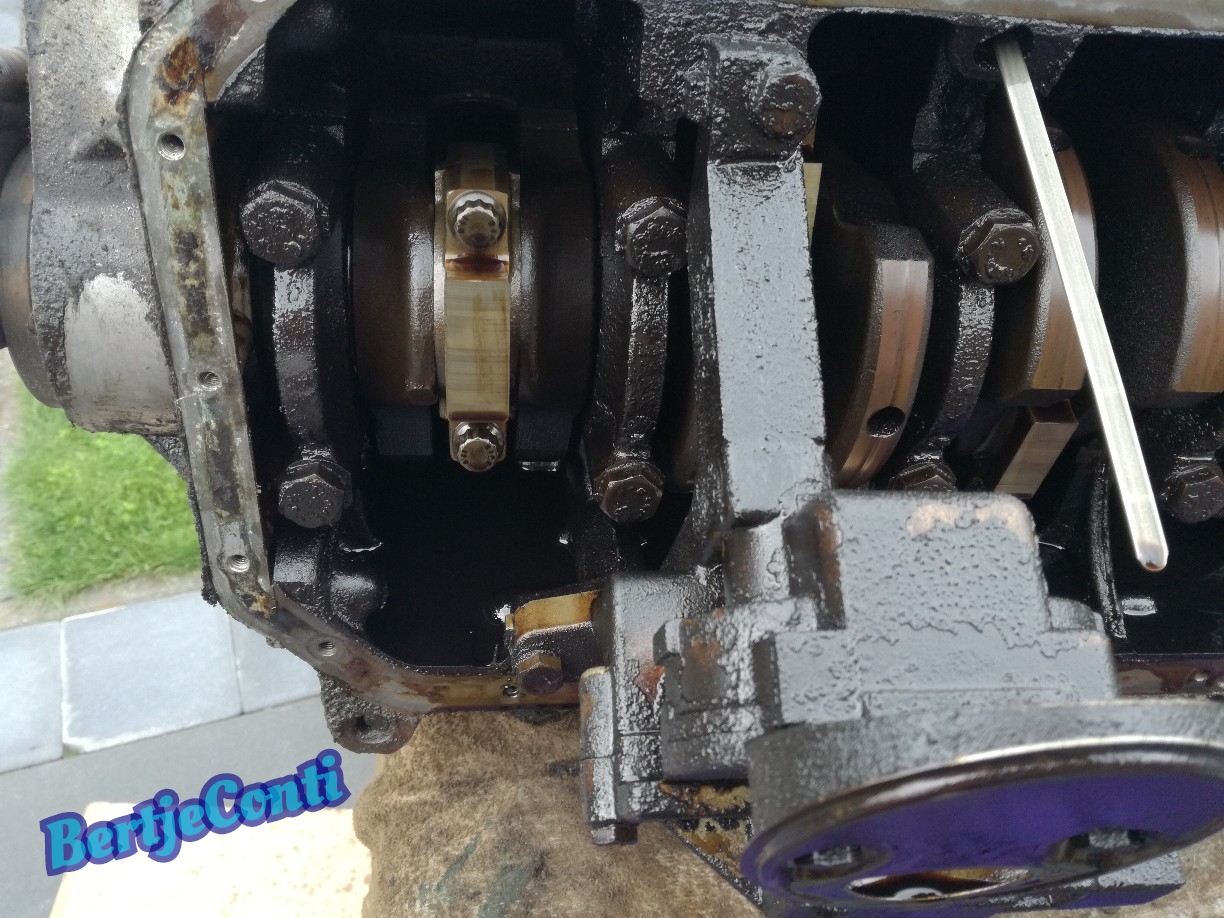

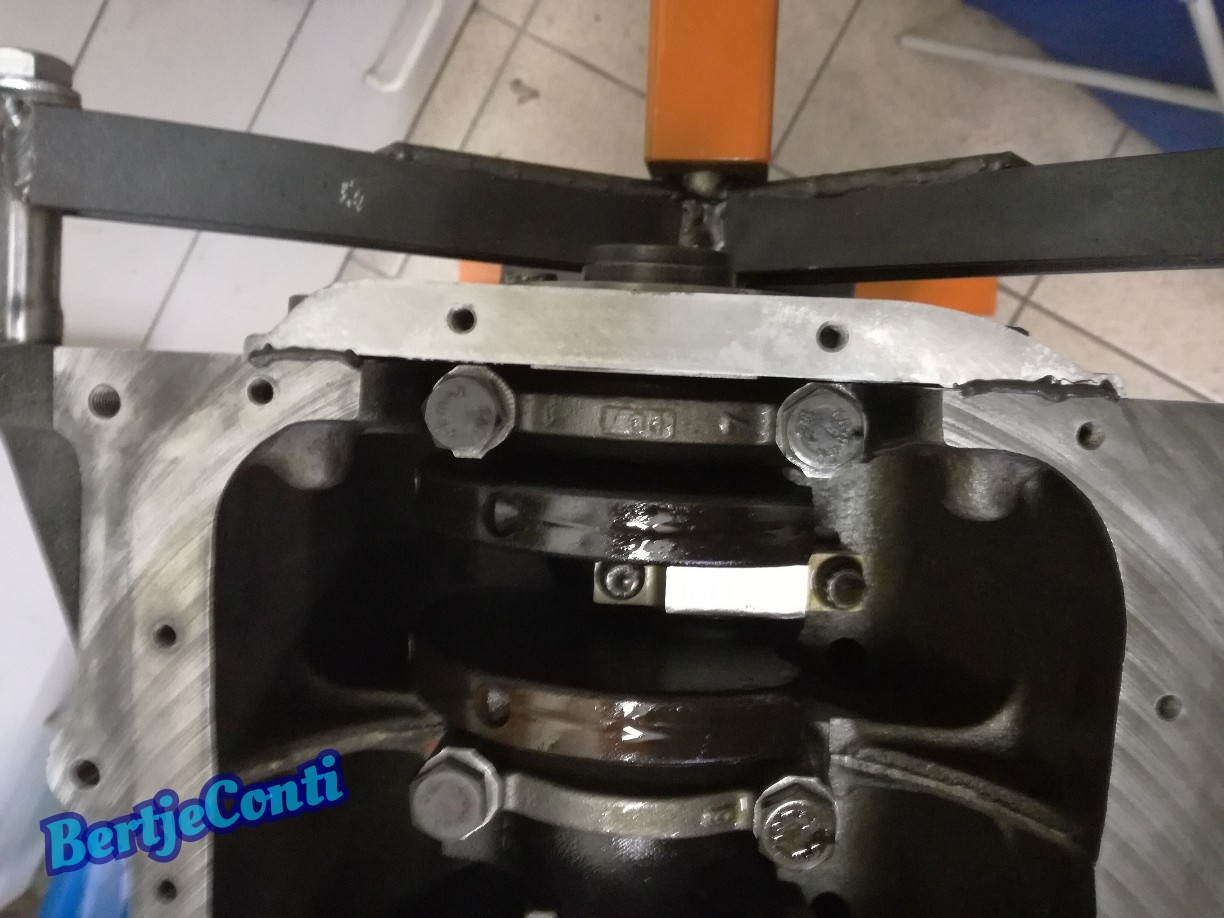

Then i checked the conrod bearing clearance also with te plastigauge method. I know it gives only a rough indication.

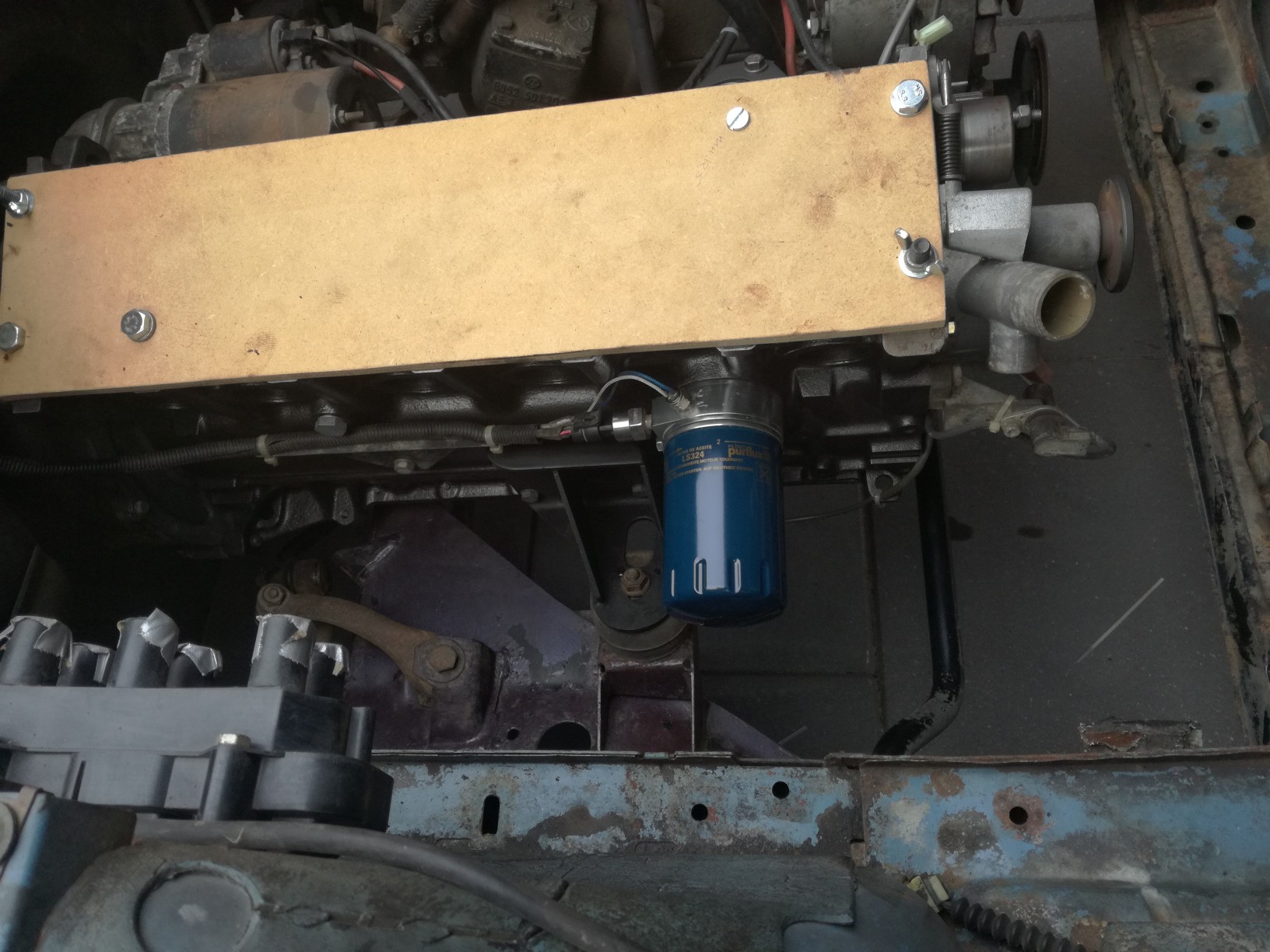

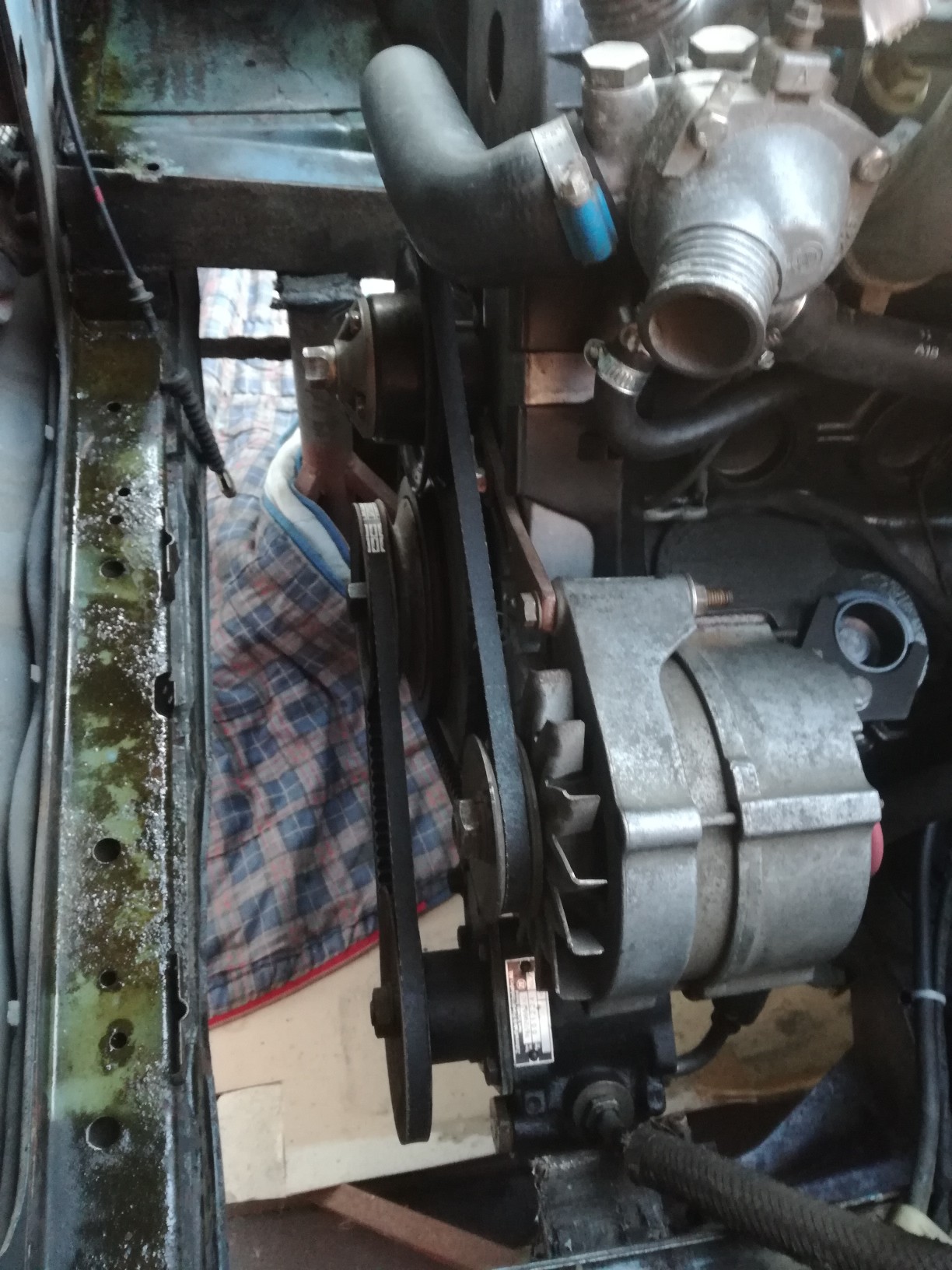

Then it was time installing the crankshaft, placing main bearing shells with lot of engine oil, i didn't use special assembly lube, because i have a plan running the oilpump before the the engine will make its first turns. This will be done when the engine is complete assembled, except for the timing belt, that way i'm able to drive the intermediate shaft with a drill and engage the oilpump without running the engine. all air will be pumped out and the oil galleries filled with oil.

With each main bearing cap installed the crankshaft turned lighter, when all main bearings were installed and the bolts tightened to spec torque the cranshaft turned that light i never expected.

I did reuse the main bearing bolts, because these bolts aren't "stretch" bolts.

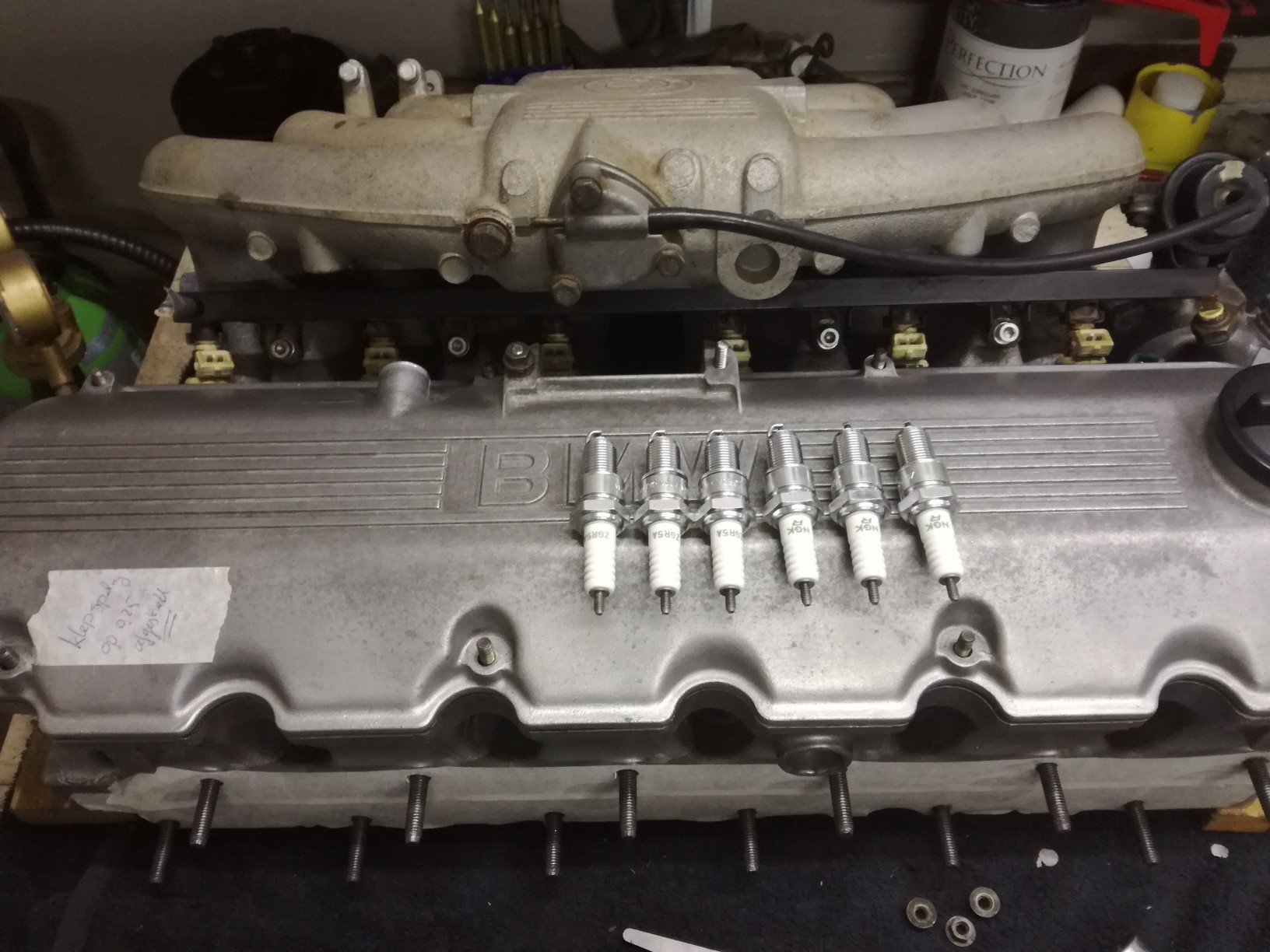

Next was checking the piston ring gap, conform manual.

5 compression rings had a 0.45mm gap, and one had a 0.5mm gap, specs say minimal 0.3mm max 0.5mm

all oil and oil control rings ha a gap 0.4~0.45 gap

This means no re-gapping required.

assembling these piston rings to the pistons was a nervwrecking job, did not like it at all, affraid braking a ring. but luckily that didn't happen, jeej.

After that installing the pistons in the engine with a piston ring compressor tool was a easy job.

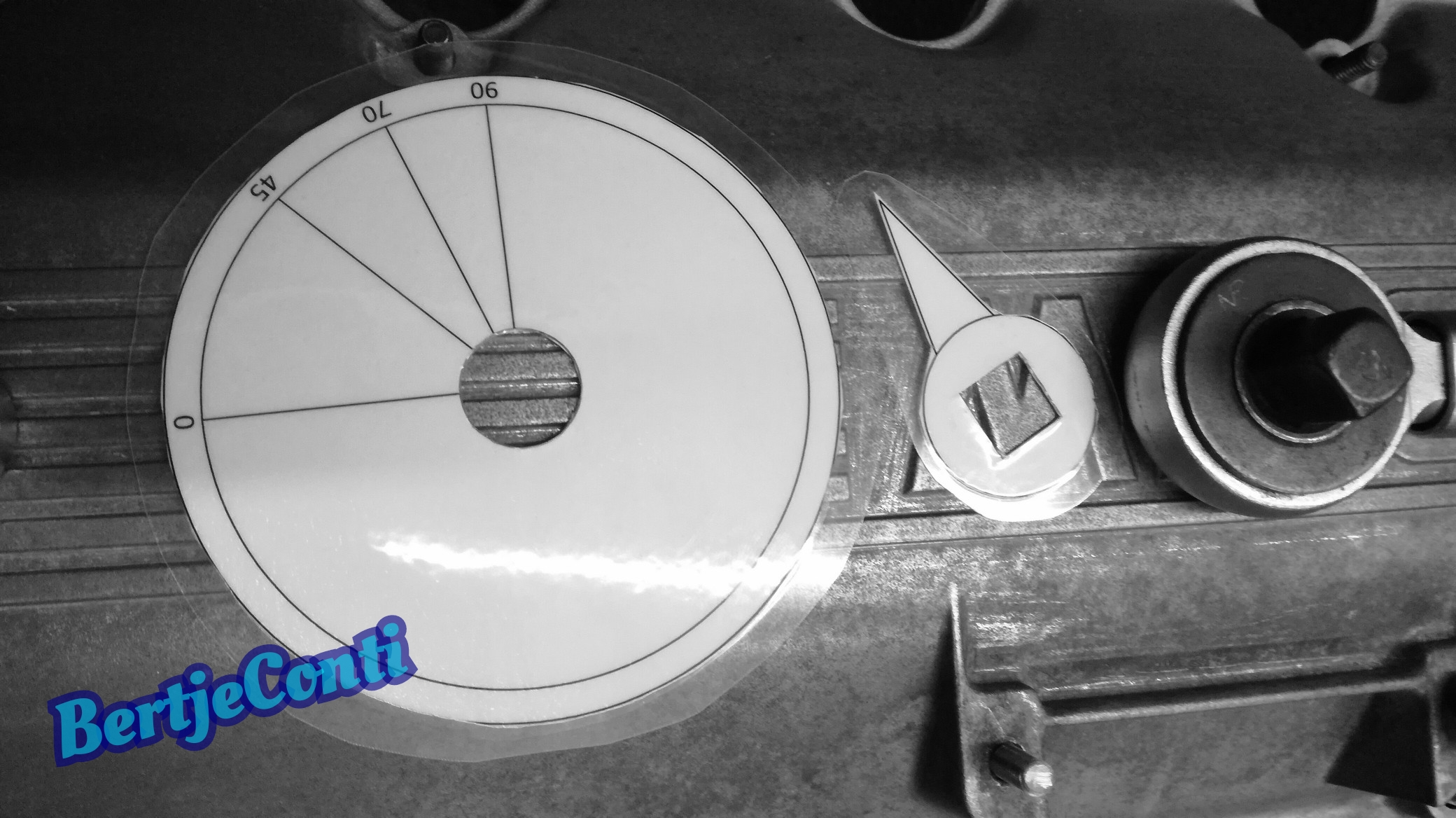

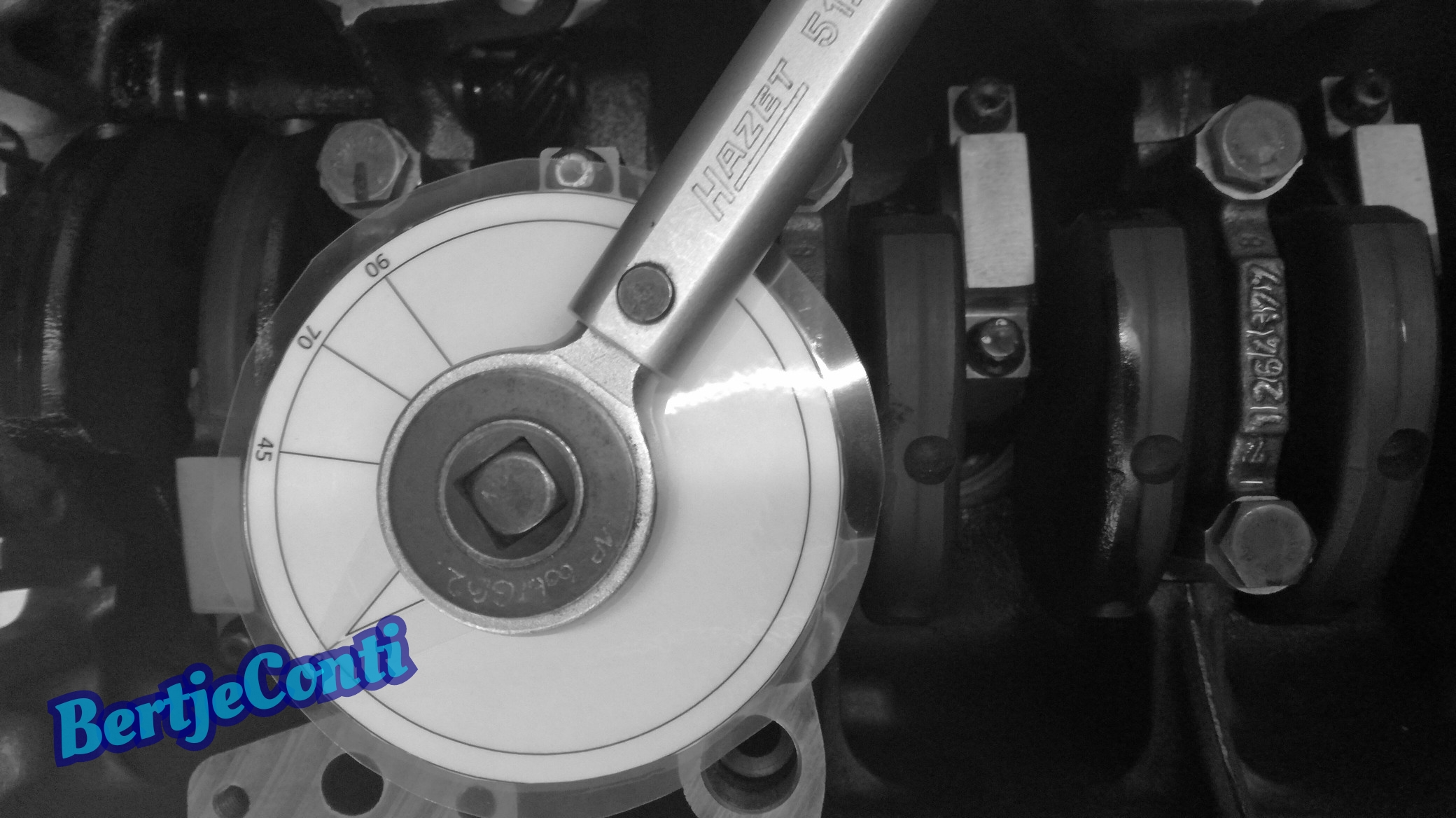

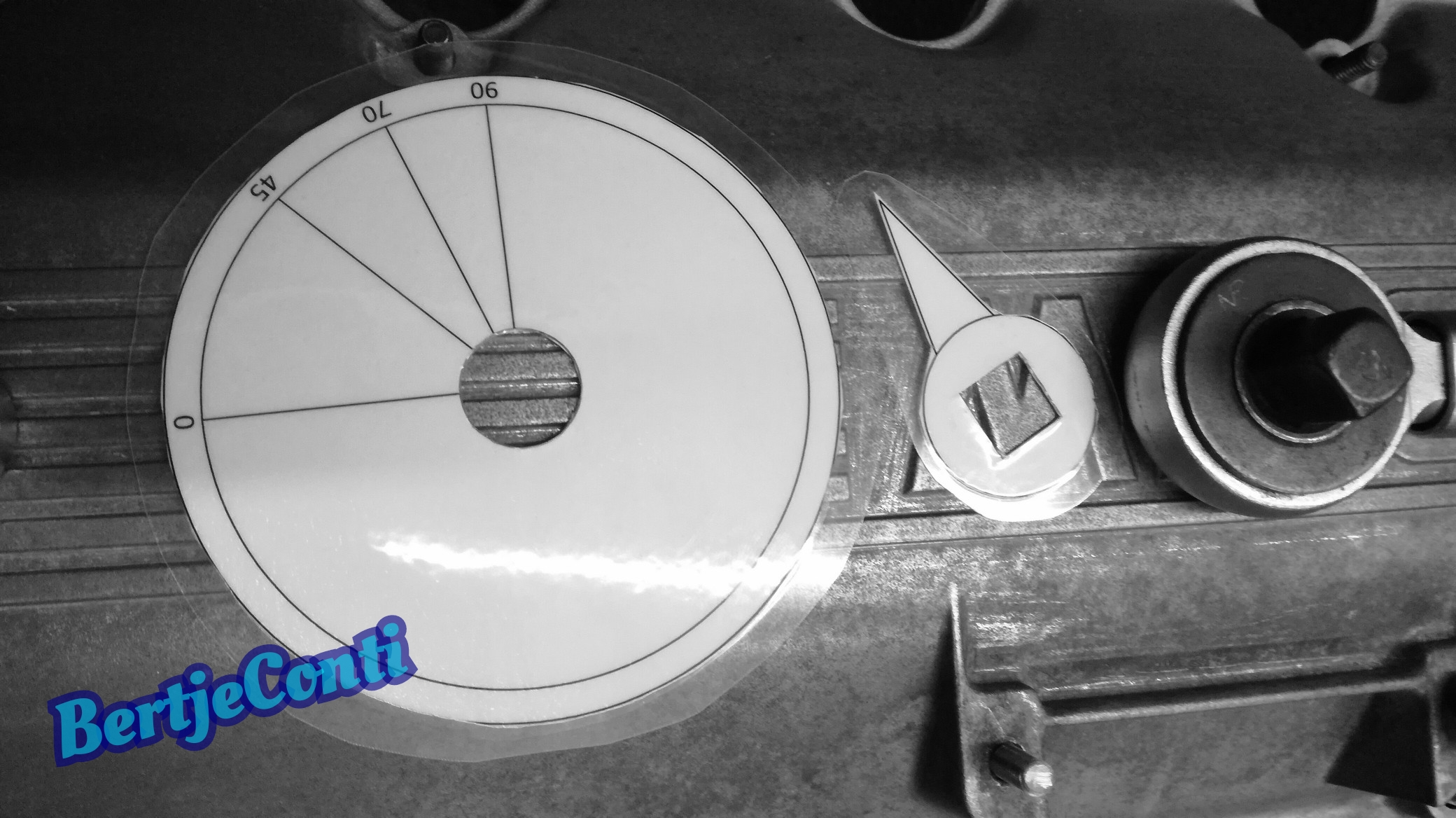

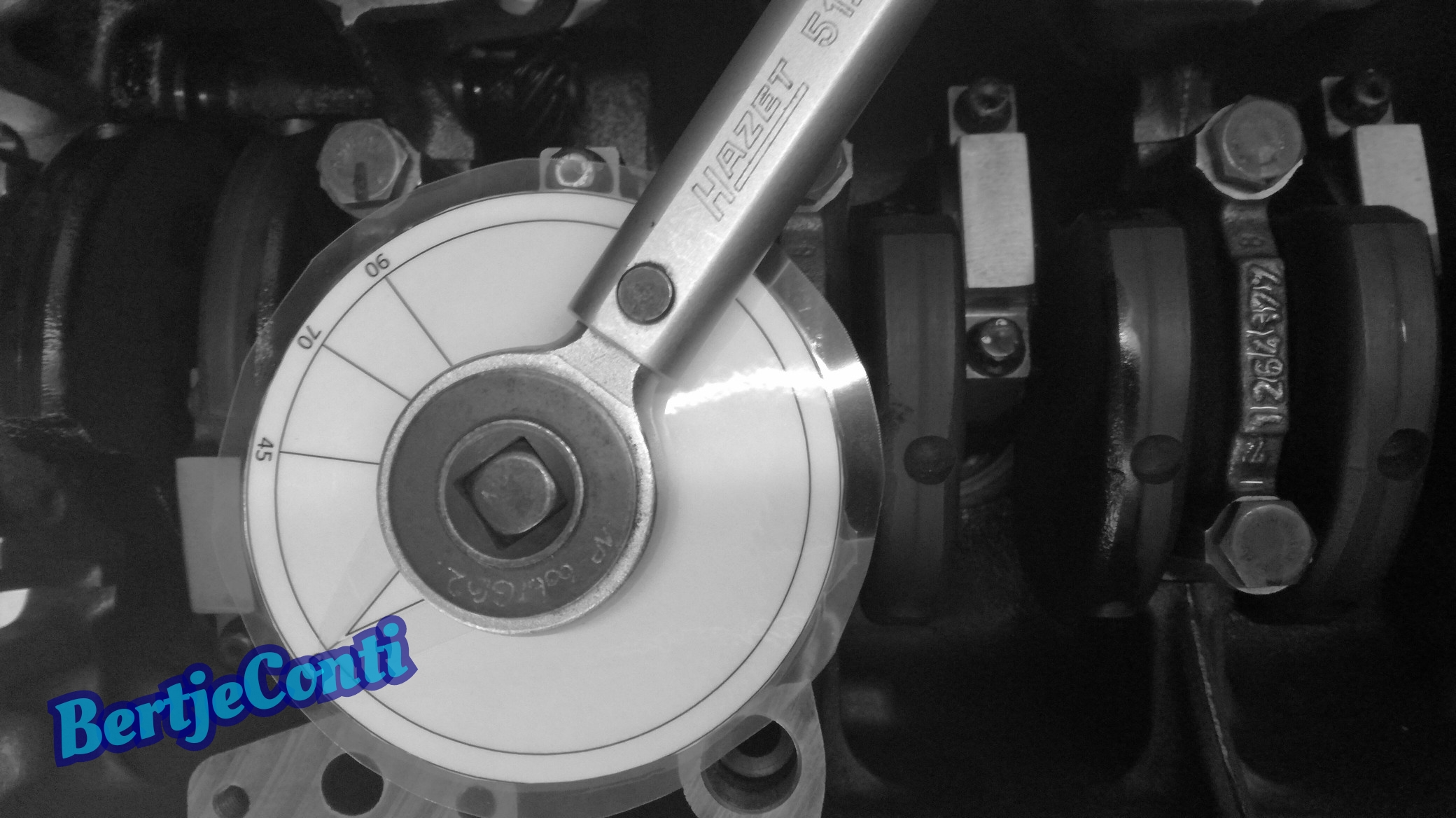

for torqing the conrod bolts i made a simple tool, these bolts needs to be torqued to 5Nm then 20Nm and then 70°, again i reused the conrod bolts, all manuals say new bolts should be used, but i didn't.

They say these bolts are stretch bolts (TTY torque to yield), but thats not entirely true. (i did extended tests with a set off these bolts and my tests confermed these bolts won't stretch plastic when torqued to spec, only elastic stretch)

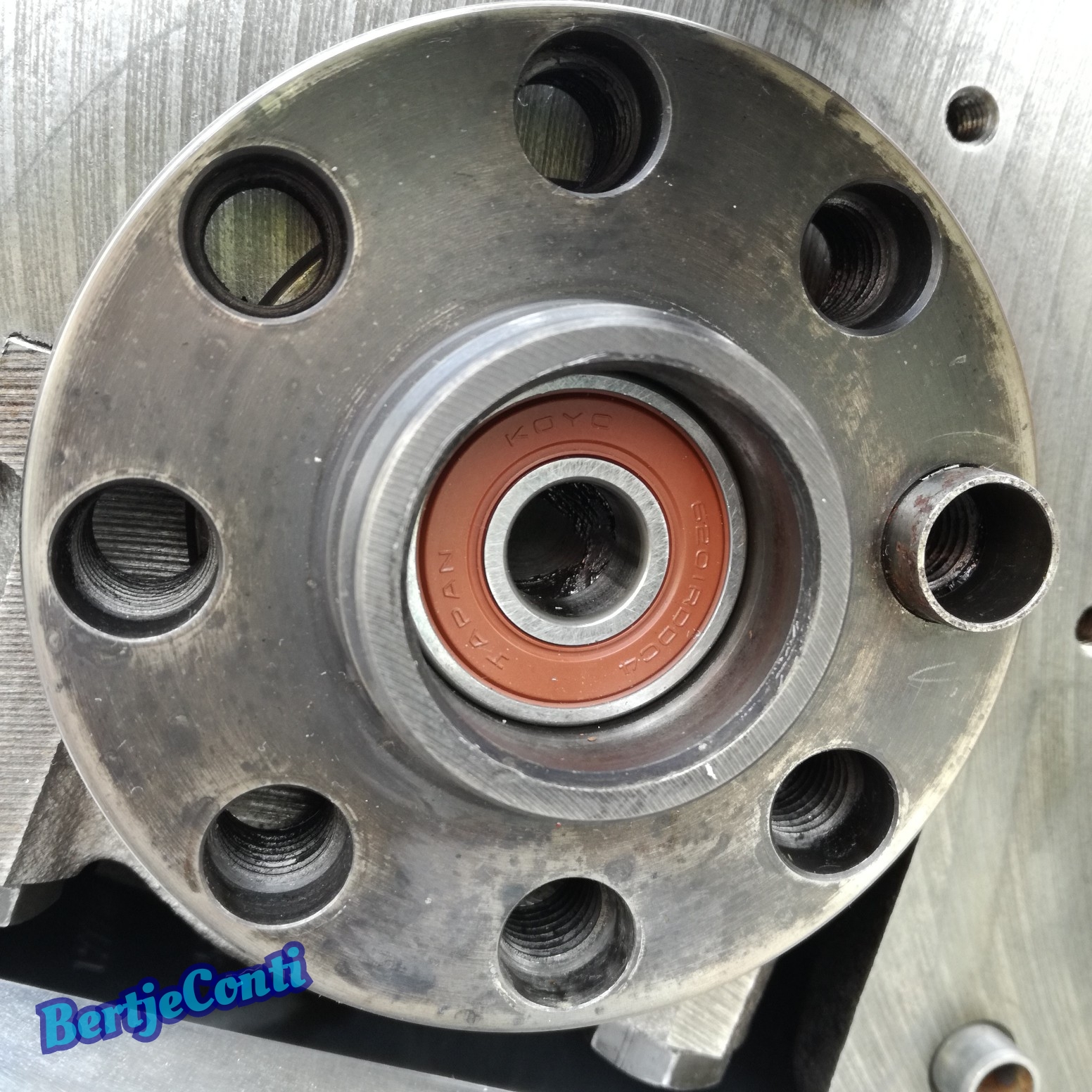

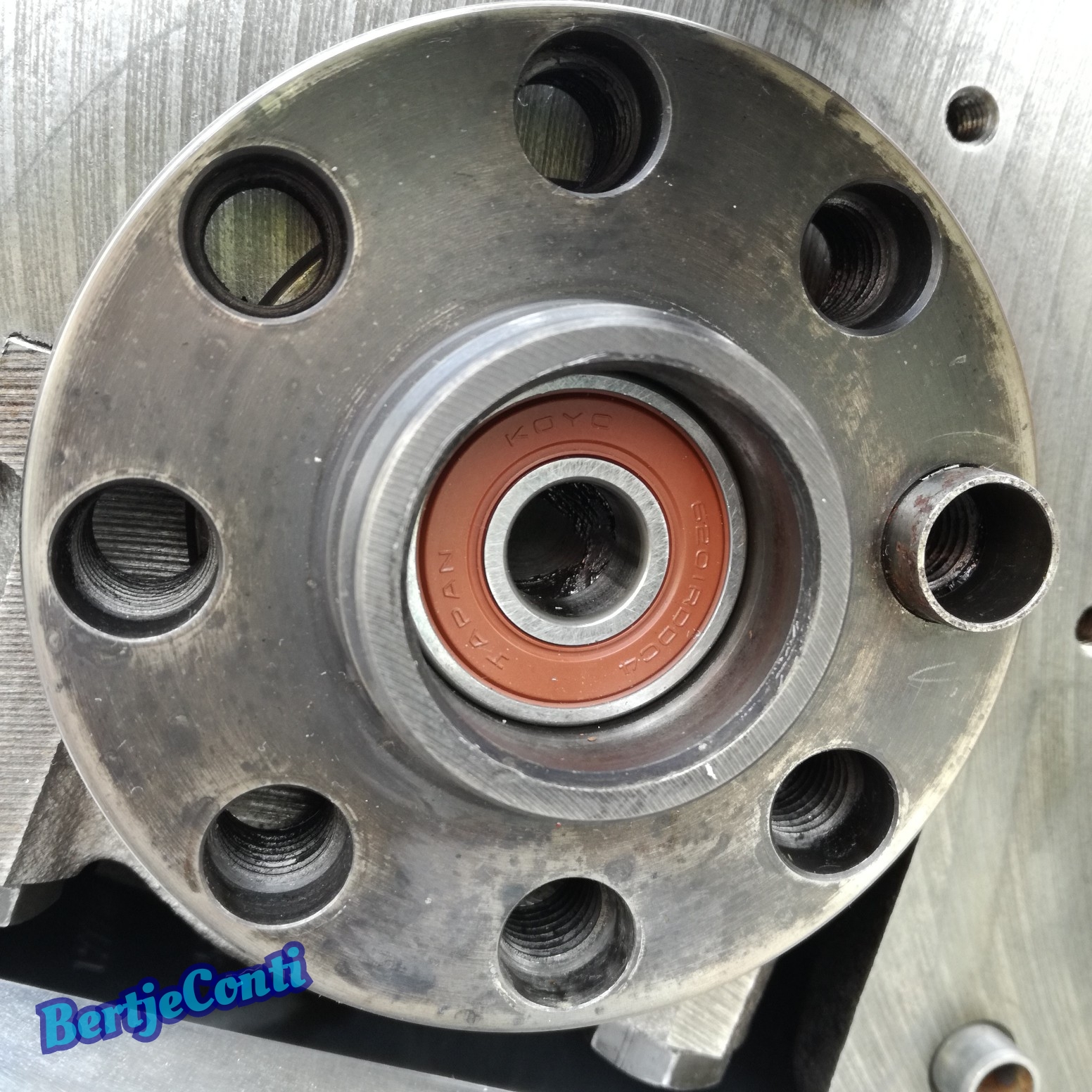

Also renewed the pilot bearing in the crankshaft and washed out the vilt oil ring with lots of brake cleaner and reoiled this ring with fresh oil:

The old protecting cap was damaged, so also replaced for a new cap

The bore for the pilot bearing had a little notch, so the bearing can't be pressed in to deep:

And placed a new needle bearing for the oil pump intermediate gear/distributer gear, installing this bearing isn't easy because it's a fragile little bearing and it's placed deep into the engine block.

I did use a old distributer and "glued" the needle bearing with grease to the shaft and then pressed the bearing in with the distributer as a guide.

"glued the bearing to the shaft"

pressed it in and removed the distributer again.

and pressed the bearing with a suitable tool further down.

the installed the intermediate gear and end cap, the end cap has the same needle bearing, this one was OK after a good cleaning job.

to be continued