Page 1 of 1

Whats so special about bmw main bearing cap bolts

Posted: Thu Apr 23, 2020 10:18 pm

by BertjeConti

I'm wondering whats so special about the M10x75 10.9 grade bmw main bearing cap bolts, used in almost all older bmw engines.

When searching on the part number you'll find these bolts, costs about €5,- to €10,- a piece.

But when i search for M10X75 grade 10.9 bolts, i can find them for about 20 euocents a piece.

Thats a huge price difference between these bolts which schould be the same, because they are both grade 10.9, which says something about the tensile strength of a bolt.

Please enlighten me.

Re: Whats so special about bmw main bearing cap bolts

Posted: Thu Apr 23, 2020 10:57 pm

by Wilmo

It is said that these are stretch bolts. When they stretch, they get stronger. The advantage is that they will only get about the specified strength and therefore the torque setting or angle setting of the bolts is less critical.

However, I havent't seen anything stretchie on the bolts in my engine... They really should show a neck with a decreased diameter.

Re: Whats so special about bmw main bearing cap bolts

Posted: Sat Apr 25, 2020 11:28 pm

by BertjeConti

As far as i know, the main bearing cap bolts are not so called tty (torque to yield) bolts like the conrod bolts.

So these main bearing bolts won't stretch so far they deform when properly torque'd. This means when losened again these bolts aren't stretched.

Thats why i don't understand why they should be replaced, and why the bmw bolts are that expensive.

Re: Whats so special about bmw main bearing cap bolts

Posted: Sat Apr 25, 2020 11:36 pm

by Wilmo

After a lot of reading of some tuners that use the old bolts and even racers that use the same bolts after a rebuilt, I decided to do so as well.

Re: Whats so special about bmw main bearing cap bolts

Posted: Sun Apr 26, 2020 12:06 am

by uwbuurman

They are BMW. So prices are ridiculous. I recently changed some parts on my BMW E91. New stuff from BMW is over 3 times more expensive then the after market parts from oem manufactorers, only difference is that the BMWmarque is grinded of....

Re: Whats so special about bmw main bearing cap bolts

Posted: Wed Apr 29, 2020 10:50 am

by BertjeConti

Wilmo wrote: Sat Apr 25, 2020 11:36 pm

After a lot of reading of some tuners that use the old bolts and even racers that use the same bolts after a rebuilt, I decided to do so as well.

And what did you do with your conrod bolts, renewed or reused?

Conrod bolts are so called TTY bolts like the cilinderhead bolts, and again very expensive, around €7,- each, compared to a set of headbolt which are available for about €20,- a set (14 pieces), thats a fraction.

I've done a test with used conrod bolts, it's all about elastic and plastic deformation. A TTY bolt should deform plastic if torqued conform spec's, which means it schould have grown in length when unbolted again. If the bolt keeps his length after unbolting, it was only elastic deformed when torqued down.

i've torqued down a conrod bolt conform specs, first 20Nm and then another 70 degrees. Then marked the exact location of the bolt to the conrod with a sharpie, and unbolted it again.

If the bolt was plastic deformed, the next time this bolt is torqed down it should go down a little further, right?

I repeated the process 5 times and each time the bolt torqued down ended exacty at the same place, not a degree more. I also could not measure any growth in length.

This experiment tells me a conrod bolt does not deform plastic when torqued down conform specification, which means they can be used again safely.

I could do the same test with a main bearing cap bolt, but these aren't tty bolts, and are torqued down way before plastic deformation occures, a test would confirm that.

Re: Whats so special about bmw main bearing cap bolts

Posted: Fri May 01, 2020 9:57 am

by Wilmo

Conrod bolts I ordered new at BMW. I assumed that these where in fact TTY because of the reduced diameter.

Look, all bolts deform, that is how the friction on the threads is built up. But as long it is elastic deformation there is no problem.

In your experiment. Can you measure the length of the bolt when it is tightened?

Re: Whats so special about bmw main bearing cap bolts

Posted: Fri May 01, 2020 10:47 am

by BertjeConti

Wilmo wrote: Fri May 01, 2020 9:57 am

......

In your experiment. Can you measure the length of the bolt when it is tightened?

Oh yes, i can, thats a good idea....

Re: Whats so special about bmw main bearing cap bolts

Posted: Fri May 01, 2020 10:04 pm

by BertjeConti

BertjeConti wrote: Fri May 01, 2020 10:47 am

Wilmo wrote: Fri May 01, 2020 9:57 am

......

In your experiment. Can you measure the length of the bolt when it is tightened?

Oh yes, i can, thats a good idea....

this was a interesting test, bolt length torqued down was 62,35 mm, and losened its length was 62,05. So when a conrod bolt is torqued down its length has grown 0.25 to 0.3 mm and this makes sense. These bolts have M9 thread with a 1.25 mm pitch.

a 70 degree turn makes 0.25mm displacement with this thread: 70/360 is about 1/5th turn and 1/5th from 1.25mm = 0.25mm

Re: Whats so special about bmw main bearing cap bolts

Posted: Sat May 02, 2020 12:51 am

by Jeroen

Re: Whats so special about bmw main bearing cap bolts

Posted: Mon May 04, 2020 12:12 am

by Wilmo

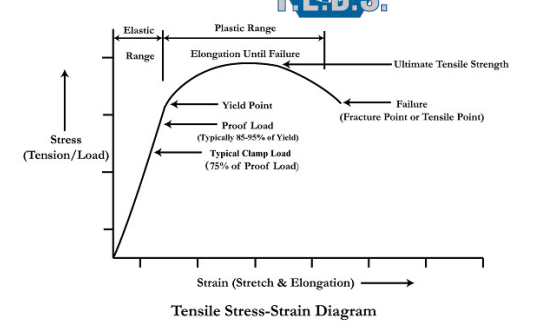

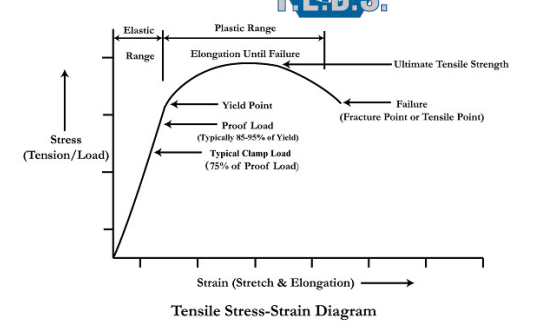

Ah, that is 5 microns per mm. See these graphs, of course I don't know the exact graph for your bolts, but you are most probably within elastic deformation.

It is important to stay under the yield strength, as the graphs shows, the proof load is about 80% of the yield strength. It depends a bit from the type of load what percentile to take, but since it is not a load that goes from tensile to compressive, the percentile can be taken rather high. In effect for a bolt are the clamping forces so high that dynamic load exerted on the bolt just results in a small variation of forces. TTY are in the area above the yield strength since steel gets stronger when elongated.

Youngs modulus for 10.9 bolts is 210GPa. For a yield strength of 940MPa this means that the it is reached at around 4-5 microns per mm.

Maybe this is where the whole story comes from. You are exactly in the 0.2% region so the bolts will probably have stretched a little bit.