Nice V8 project

- Jeroen

- Site Admin

- Posts: 29990

- Joined: Tue Sep 14, 2004 12:23 pm

- My E21(s): '81 323i Baur

- Location: The Netherlands

- Contact:

Re: Nice V8 project

Well especially the outside might be a matter of taste, but I do love the way you go about on the suspension atm! Any idea when you want this all to be finished, as far as it will ever be finished ofcourse!

And I must say I sometimes get the idea you only get your share of replies if your're from the UK, here on the english part of the forum. That might also be the reason why we see visitors from other countries less and less here and that is a sad thing. Means I will be watching the UK in-crowd closer, I want this place to remain THE E21 place for all!

And I must say I sometimes get the idea you only get your share of replies if your're from the UK, here on the english part of the forum. That might also be the reason why we see visitors from other countries less and less here and that is a sad thing. Means I will be watching the UK in-crowd closer, I want this place to remain THE E21 place for all!

Regards/groeten, Jeroen

Re: Nice V8 project

thank Jeroen. I had hoped to have the suspension finished months ago, but can't lift a spanner until the legal stuff is signed off first and this meant paperwork and waiting on other people who don't necessarily care too much for how long they take. I do hope to get it road legal by the end of the year (although I've been saying this for the last five years...  ). After that its just paint and interior finishing to get it to 'finished' standard, which is just a matter of how quickly I can save. It will by no means be 'finished' though, as I've got plenty more plans in the works.

). After that its just paint and interior finishing to get it to 'finished' standard, which is just a matter of how quickly I can save. It will by no means be 'finished' though, as I've got plenty more plans in the works.

[img]http://i161.photobucket.com/albums/t218/340i/drift340i.jpg[/img]

Re: Nice V8 project

after 5 months, i finally received my custom wheel lips and BBS centre caps! its been an absolute nightmare getting the supplier to deliver these (I thought I was going to get completely screwed over), then they turned up and they're not perfect fitment and one is scratched pretty bad too! pretty annoying, but what can you do?

anyway, they should still be good once i paint the centres and re-polish the lips.

heres the first mockup of the rears. enjoy....

i think they're going to be wide enough for the little e21?

anyway, they should still be good once i paint the centres and re-polish the lips.

heres the first mockup of the rears. enjoy....

i think they're going to be wide enough for the little e21?

[img]http://i161.photobucket.com/albums/t218/340i/drift340i.jpg[/img]

Re: Nice V8 project

ha ha ha ha ha - nice!!!!!!!!

are you going to leave the centers silver?

are you going to leave the centers silver?

BMW e21 - 320tsi - Project Rajay

Audi 50 RS

1/2 a BMW 2002 tii - Project Nipon

Smart 4/2 84bhp cabriolet - Company car

Audi 50 RS

1/2 a BMW 2002 tii - Project Nipon

Smart 4/2 84bhp cabriolet - Company car

Re: Nice V8 project

haha thanks guys. the plan at the moment is to do gloss black centres.

In other updates...

Due to the stupid laws around custom built suspension in NZ, I've been held up for a few months with getting approval for my new designs for the front end and also I had to re-do the threaded inserts.

Basically, because the inserts that were made could only be welded 90% of the circumference of the tube (due to space limits on one side the welder physically couldnt get in there), it was rejected by the certifier (they must have a 360 degree weld and full x-ray test to prove the quality of the weld). The new setup has been made so that it presses in where the original shock tube goes, but is actually inside the cut-down shock tube (rather than replacing it). There is a rule here that says it is illegal to weld to any cast/forged suspension components (even though the original design did this). What I've done is to convince the certifier that I have had the insert welded to the original tube, not to the casting. Rediculous, I know, but welding to weld is legal and welding to a casting is not...

the stupid thing about the new setup (other than having to do it twice) is that there is actually less weld on it now than the old one!

on the plus side, the new setup allows the shock to be mounted another 10mm or so lower, and i think they look better (almost oem?)

In other updates...

Due to the stupid laws around custom built suspension in NZ, I've been held up for a few months with getting approval for my new designs for the front end and also I had to re-do the threaded inserts.

Basically, because the inserts that were made could only be welded 90% of the circumference of the tube (due to space limits on one side the welder physically couldnt get in there), it was rejected by the certifier (they must have a 360 degree weld and full x-ray test to prove the quality of the weld). The new setup has been made so that it presses in where the original shock tube goes, but is actually inside the cut-down shock tube (rather than replacing it). There is a rule here that says it is illegal to weld to any cast/forged suspension components (even though the original design did this). What I've done is to convince the certifier that I have had the insert welded to the original tube, not to the casting. Rediculous, I know, but welding to weld is legal and welding to a casting is not...

the stupid thing about the new setup (other than having to do it twice) is that there is actually less weld on it now than the old one!

on the plus side, the new setup allows the shock to be mounted another 10mm or so lower, and i think they look better (almost oem?)

[img]http://i161.photobucket.com/albums/t218/340i/drift340i.jpg[/img]

Re: Nice V8 project

soooooo, its been way too long with zero progress on the 340i so i thought id do an update. ive been spending all my time and money on my new ute project (http://www.youtube.com/pimppalacecustoms) but have decided to get stuck back into the bmw, since i think its been too long in the build (almost 9 years now i think...  ) and needs to be finished! (well, driving anyway). ive got myself a welder now, so the plan is to get the bmw transported from storage to my house, get into fabricating and get shit done. last year i was having strong thoughts about boost, but have flagged that idea since the ute will be getting turbo'd. the current plans mainly focus on filling all the holes i cut out of the chassis and body, setting the suspension up much better, and getting much more lowwwwww

) and needs to be finished! (well, driving anyway). ive got myself a welder now, so the plan is to get the bmw transported from storage to my house, get into fabricating and get shit done. last year i was having strong thoughts about boost, but have flagged that idea since the ute will be getting turbo'd. the current plans mainly focus on filling all the holes i cut out of the chassis and body, setting the suspension up much better, and getting much more lowwwwww

stay tuned...

stay tuned...

[img]http://i161.photobucket.com/albums/t218/340i/drift340i.jpg[/img]

Re: Nice V8 project

got the car on axle stands and stripped today - doors, side windows, rear window, boot and hinges, and dropped the rear end out. cutting to start tomorrow and welding next week!

ive also made the decision to ditch my four recaro seats and just run twin buckets, as id like to eventually add a cage and go drifting with it. with what ive got planned for the rear suspension, there isnt going to be room anymore for rear seats anyway...

another thing ive added to the list is to fix the b pillar rust that ive been ignoring for a loooong time

ive also made the decision to ditch my four recaro seats and just run twin buckets, as id like to eventually add a cage and go drifting with it. with what ive got planned for the rear suspension, there isnt going to be room anymore for rear seats anyway...

another thing ive added to the list is to fix the b pillar rust that ive been ignoring for a loooong time

[img]http://i161.photobucket.com/albums/t218/340i/drift340i.jpg[/img]

Re: Nice V8 project

ok time for an update. since im going two seater with this, i figured i may as well do a little trimming to the sheetmetal in the back of the car so that i can raise the subframe and enable good suspension geometry and good stance. im starting with the back end and then will do the front once all this is done.

i had the rear subframe modified a few years back to fit the nissan R200 diff (and custom hubs, custom axles, big brakes, etc), but to raise it up what ive done so far is to bin the oem front mounts and weld in plates that will make it solid-mounted (it will be harsher, but idgaf lol). the rear pickup will be custom made.

onto the pics...

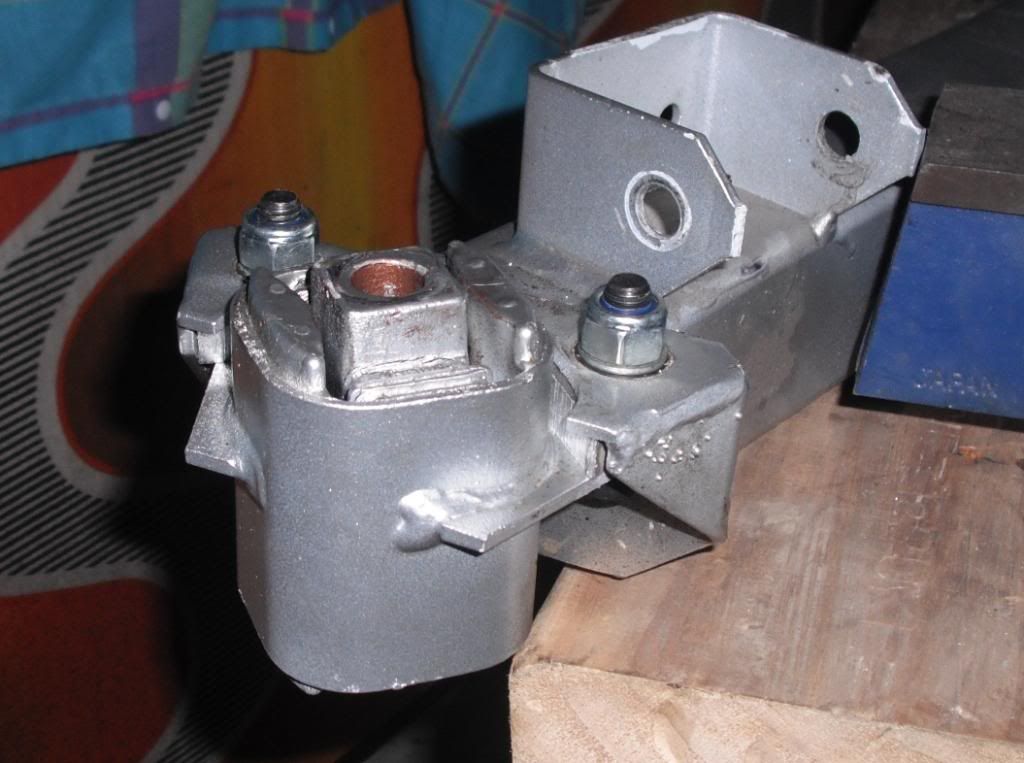

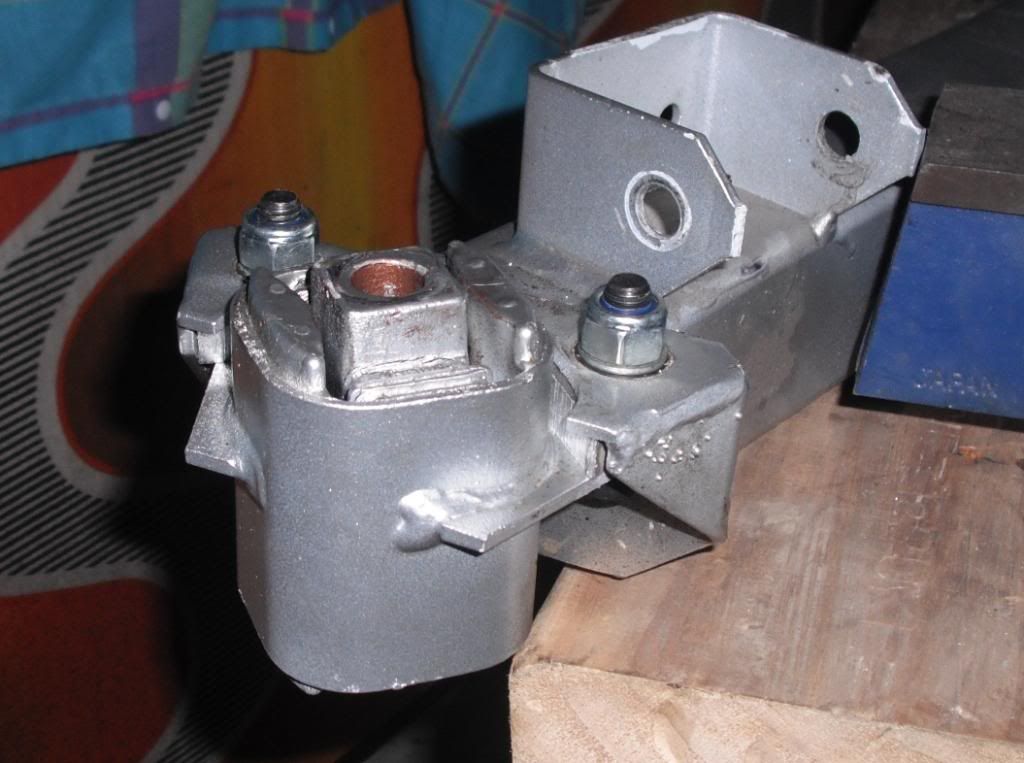

heres the oem mount, when i was going to have it 'flipped' and spaced. normally it is the other way up and there is no spacer.

here is where im at now, spacer and mount gone, replaced by a triangle piece of steel with hole in it, welded in. i havent measure it, but think it might raise the subframe like 2-3" or so.

to secure it, im using a crush tube and the original washer and nut (ill get a beefier one made up once the design is finalised, plus theres a bottom plate that goes on too)

raising it this much helps reduce the rear camber a little, but needs a bit of trimming to make it fit (im going to weld stuff back in to strengthen it all up eventually)

now to test fit with my wheel adaptors (5x120-5x114) and bits from my wheels im going to build

the rear flares will be extended so there is less poke.

and with the m5 replicas i was going to run (17x8)

from here i found that i havent even nearly raised the subframe enough to solve the problem i wanted to fix. look at this filthy semi trailing arm angle!

and the camber...

so where im at now is i dropped the wheel down until the camber is how i want it, then measured the difference, and that will be how much extra i have to raise the subframe (another 3"... haha)

from there, the axles will also be reasonably level and the diff has more ground clearance, which are bonuses.

and thats it for today. comments and questions welcome

i had the rear subframe modified a few years back to fit the nissan R200 diff (and custom hubs, custom axles, big brakes, etc), but to raise it up what ive done so far is to bin the oem front mounts and weld in plates that will make it solid-mounted (it will be harsher, but idgaf lol). the rear pickup will be custom made.

onto the pics...

heres the oem mount, when i was going to have it 'flipped' and spaced. normally it is the other way up and there is no spacer.

here is where im at now, spacer and mount gone, replaced by a triangle piece of steel with hole in it, welded in. i havent measure it, but think it might raise the subframe like 2-3" or so.

to secure it, im using a crush tube and the original washer and nut (ill get a beefier one made up once the design is finalised, plus theres a bottom plate that goes on too)

raising it this much helps reduce the rear camber a little, but needs a bit of trimming to make it fit (im going to weld stuff back in to strengthen it all up eventually)

now to test fit with my wheel adaptors (5x120-5x114) and bits from my wheels im going to build

the rear flares will be extended so there is less poke.

and with the m5 replicas i was going to run (17x8)

from here i found that i havent even nearly raised the subframe enough to solve the problem i wanted to fix. look at this filthy semi trailing arm angle!

and the camber...

so where im at now is i dropped the wheel down until the camber is how i want it, then measured the difference, and that will be how much extra i have to raise the subframe (another 3"... haha)

from there, the axles will also be reasonably level and the diff has more ground clearance, which are bonuses.

and thats it for today. comments and questions welcome

[img]http://i161.photobucket.com/albums/t218/340i/drift340i.jpg[/img]