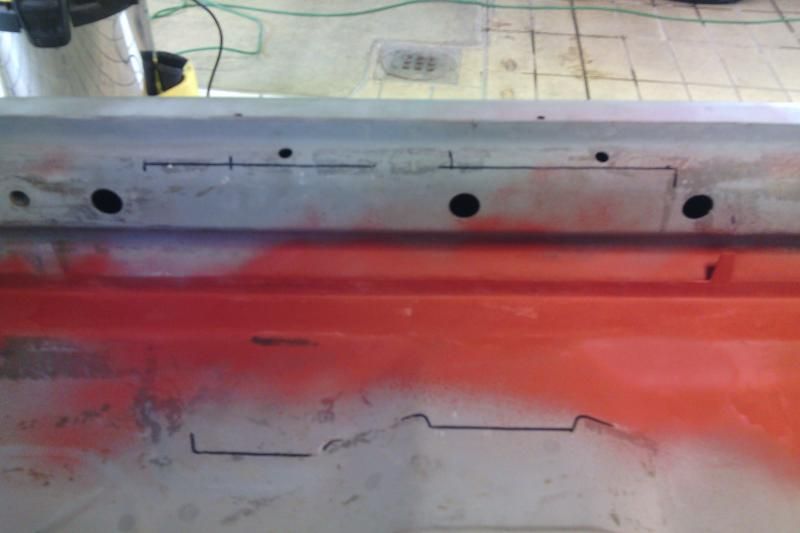

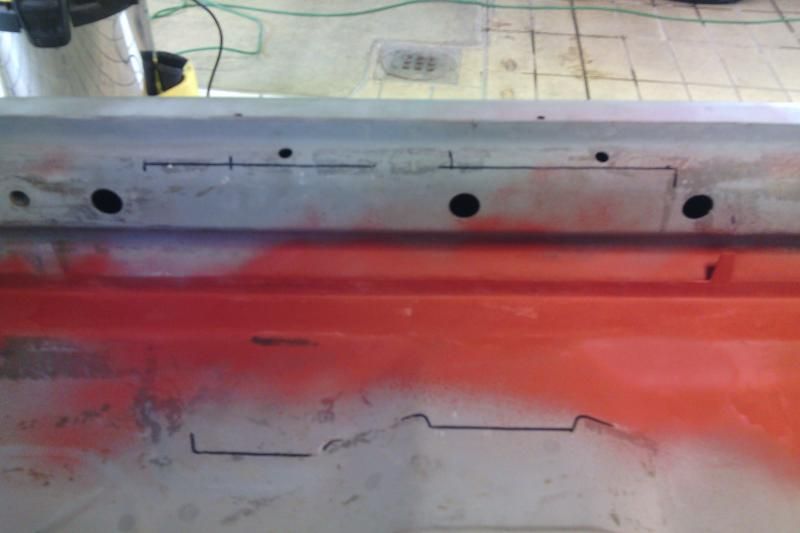

Having the weld all grinded down, I drilled the holes for the remounting of the fuel and brakeline mountingpoints.

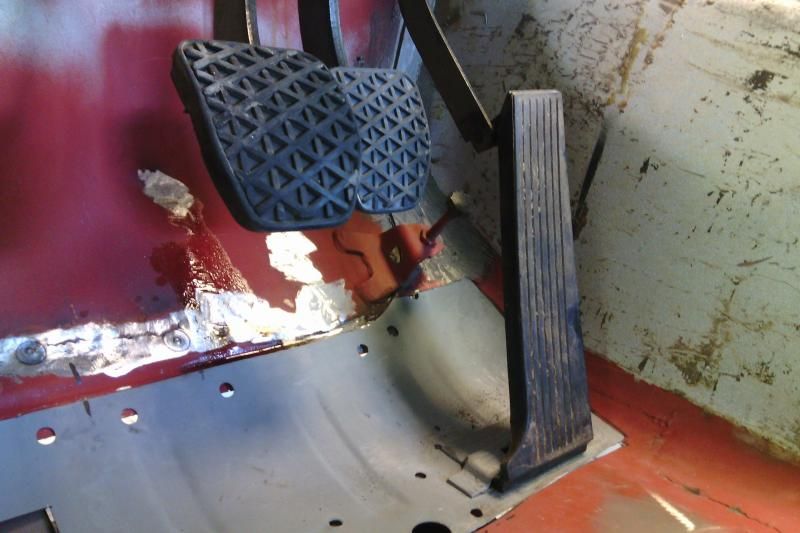

The bushes are welded, but a pic has tob e made (other day…) But now it’s time to get the seatmoutingbracket back in to place. Closer inspection learns that metalfatigue has gotten the bst of it, lots of rips in the metal.

Type 1 cars have different brackets then type 2. Type 1 have high btackets on both sides of the chair, where type 2 has a high side at the sill and a low side in the middle of the car. Mine is a type 1, but one of the last, so I have a type 2 inner bracket (low) and a high type 1 bracket at the sill side. The high one BMW improved later for the type 2. They have reinforcements where mine is cracked. So the problem was already known in 1978.

At one side: 1 on the edge, 1 appox. 5 mm llower on where the claps go on, one another 5mm lower, 1 across the hole, also on the other side of the hole and one underneat the cableclamp, which you can’t see on the pic. On the other side of the bracket all the same. So in total 10(!) cracks in the metal duet o fatigue….

Welded all the cracks and repaired the edge.

All fixed and in the primer.

Outlined the position. Next time I’ll weld it in.