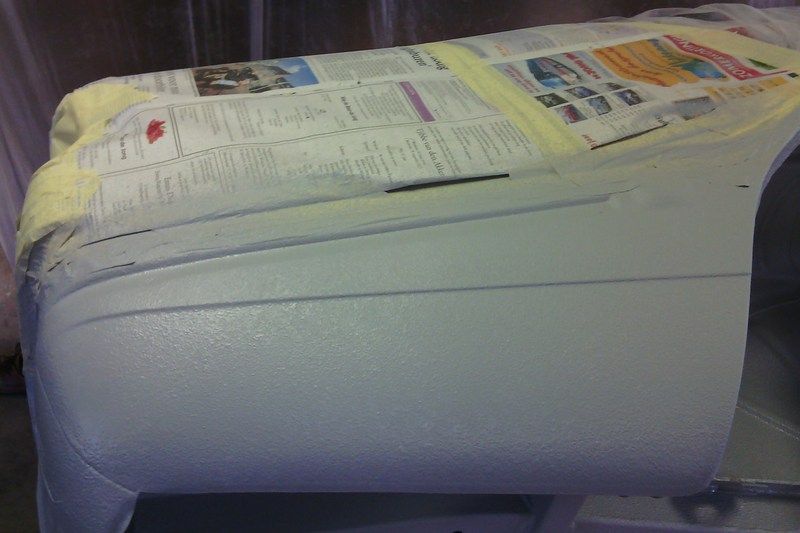

Now the car is gone for paint, I have some time for other chores. I went on with my popout windows, for which I bought those Chinese screws. But those screws were too long, so I cut them off. The head of the screw is slightly too thick for the lower moulding, so I grinded it down, because I didn't want them to scratch the lower moulding. After that I had the screws zincplated.

Two normal and two grinded heads.

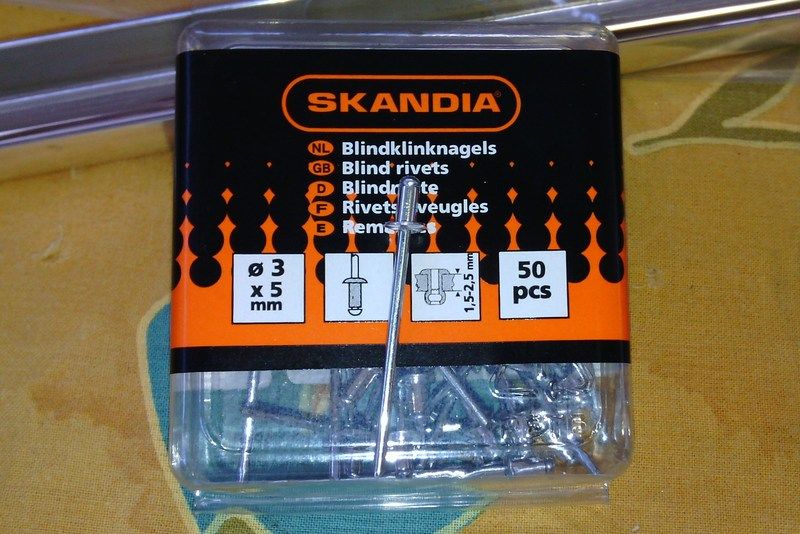

Besides the screws, I need some ribbets to put it all together. I found these blind rivets, 5mm long and 3mm thick. Perfect fit.

And put it together.

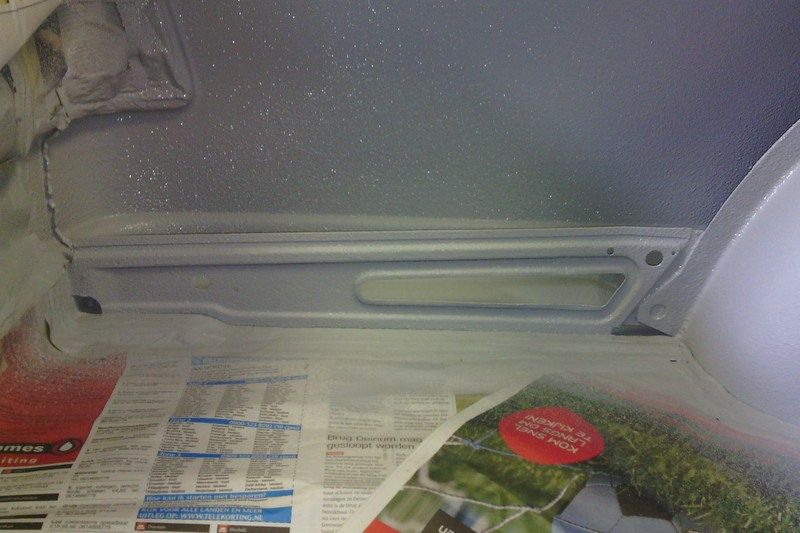

Mouldings, rubber and glass.

And this is what a brand new pop out window looks like. New mouldings (NLA), new rubbers (freakin’expensive), new glass (long, long wait)

To put the glass in the rubber and that in the mouldings, you need some lubricant. I used Dinitrol, which preserves the mouldings and metal connection angles. I ordered those angles at BMW’s. The upper one, 90 degrees, is NLA. So they send me the 60 degrees one, double. But as I tried tob end it to use it fort he upper corner, it didn’t fit. All three angles are only usable fort he corner that theay are meant for. The holes don’t line up on the other corners.